LEED 2012 – 3rd Public Comment – MR (Materials and Resources) Section

Key changes in the the MR section of LEED-NC (part of LEED BD&C) in the third public comment draft of LEED 2012 are discussed below. Do you have comments or questions on this draft? Discuss them below with your fellow LEED professionals. Substantive comments submitted here during USGBC's third public comment period here will be submitted to USGBC and considered "official" public comments.

More information on LEED 2012 certification and the third public comment.

With this third draft, USGBC delivers yet another gut rehab of the MR section. First, the more minor changes.

The Storage and Collection of Recyclables prerequisite now adds collection of batteries, mercury-containing lamps, and electronic waste.

Another new prerequisite, Construction and Demolition Waste Management Planning, gets a shift in focus. Rather than a 20% diversion minimum, the credit calls for a process shift in which a project would establish diversion goals, identify at least five materials targeted for diversion, detail diversion strategies, put in place specific contractor processes, and require reporting at the end. Alternative Daily Cover (ADC) would not qualify as diverted debris.

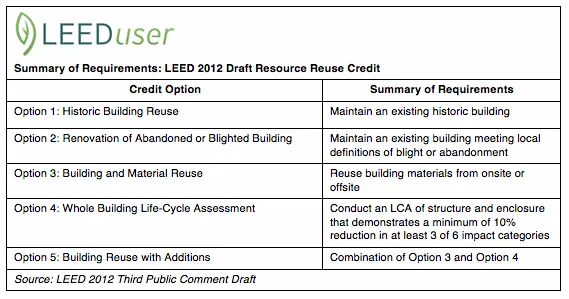

A new credit, Resource Reuse (changed from Environmentally Friendly Construction and Enclosure in the previous draft), would replace the former Building Reuse credit and incorporate Life Cycle Assessment (LCA). This lengthy credit includes four options, summarized in the table.

In general, credits for transparency and performance have been broken up since the last draft. The new credit Non-Structural Materials Transparency is gone, along with Environmentally Preferable Non-Structural Products & Materials—Prescriptive Attributes. Responsible Sourcing of Raw Materials has been renamed Responsible Extraction of Raw Materials, and the Avoidance of Chemicals of Concern in Building Materials now offers two points. Disclosure of Chemicals of Concern has been broken out of that credit into its own category. The overall aim appears to be to balance forward-looking transparency incentives with incentives for performance leadership in the here and now. These credits are summarized in the table.

These credits represent a second complete overhaul of the MR section since the first public comment period, with the old Certified Wood, Regional Materials, Recycled Content, and Materials Reuse credits, along with the new Biobased Materials credit all being jettisoned.

What do you think of the proposed changes? Make your public comments below.