Four Embodied Carbon Questions from the LEED v5 Public Comment Periods

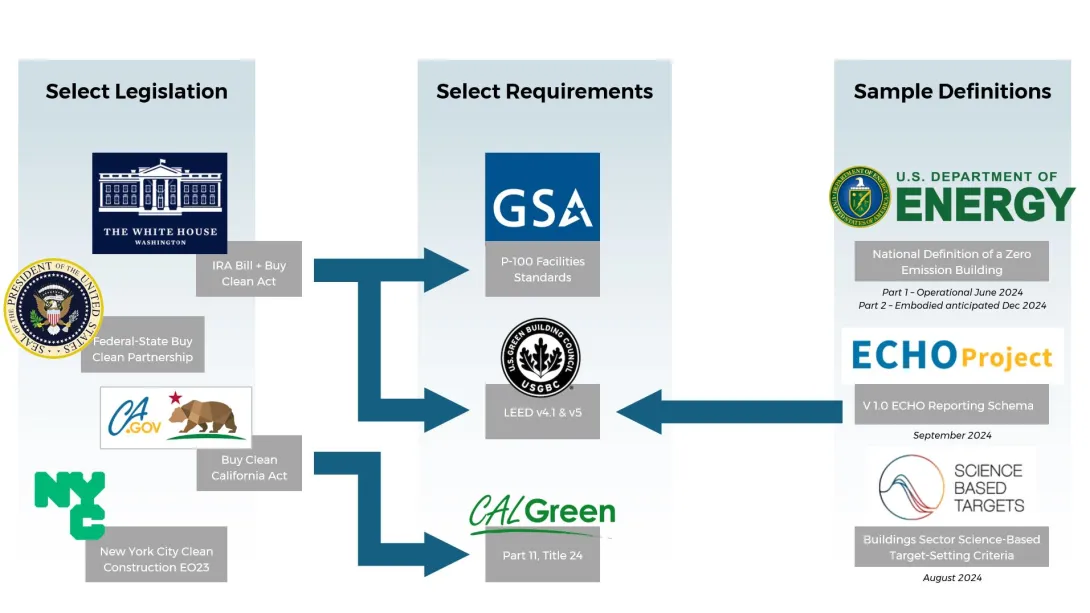

New and upcoming embodied carbon regulatory and policy landscape, pending potential changes from a new administration.

The path to decarbonizing the built environment has shifted dramatically in recent years as we’ve learned more about the urgency of embodied carbon.

We’re now paying a lot more attention to upfront embodied carbon—the carbon emissions associated with the production, transportation, and assembly of building materials—as a critical metric for assessing a building's environmental footprint. As discussions continue to evolve and regulations tighten, it's essential that we continue learning and pushing for better data and standardization of embodied-carbon best practices for both materials and whole buildings.

LEED v5 can help that happen by answering these four questions.

1. How is the regulatory landscape changing?

Reporting requirements for the full spectrum of greenhouse gas emissions are growing in jurisdictions around the world.

Under Greenhouse Gas Protocol (GHGP) standards and the recent Buildings Sector Science-Based Target-Setting Criteria, the embodied environmental impact of materials purchased and installed in buildings falls under scope 3, a tough-to-tackle but increasingly visible sector for both clients and the AEC industry.

Governments and organizations worldwide are enacting legislation and developing voluntary standards to tackle this pressing issue. California, Vancouver, New York, and the European Union are among the jurisdictions implementing measures to reduce embodied carbon in buildings. Industry standards are also catching up thanks to ASHRAE/ICC 240P and the New Buildings Institute.

Voluntary initiatives like the Embodied Carbon Harmonization and Optimization (ECHO) Project and the Science Based Targets initiative (SBTi) are providing guidance and setting targets for the industry. While these standards, particularly SBTi, are still in the pilot phase and may not yet be widely applicable to AEC teams, they signal a concerted effort to drive change and foster collaboration within the industry.

Several of the newer federal and local embodied carbon legislations are in jurisdictions that already require LEED for various project types. LEED can play a role by supporting jurisdictional efforts in whole-building embodied carbon reductions by aligning and encouraging good performance.

2. Are prescriptive or performance paths more effective?

Since its inception, LEED has recognized the importance of embodied carbon, albeit under different names. Early versions of LEED included incentives for building reuse, construction waste management, material reuse, recycled content, and other strategies for addressing product and construction impacts.

With each iteration, LEED has taken steps to refine its approach, moving from prescriptive measures like the ones listed above, to performance-based assessments—namely, product lifecycle assessments (LCA), whole-building LCA (WBLCA), and whole-building embodied carbon targets which quantify impact reductions rather than using proxies like recycled content.

From proxies to quantification

The Environmental Product Declarations (EPD) credit rewards project teams for selecting products that come with disclosures about environmental impacts, including global warming potential (GWP). Selecting products that demonstrate performance improvements in their environmental footprint can help teams earn a second point here.

Pilot Credit MRpc132, Procurement of Low-Carbon Construction Materials, goes one step further to catalyze industry-wide improvements by utilizing and growing data to help practitioners compare their selected materials to a credible baseline.

WBLCA: all about performance

In LEED v4.1, the Building Life-Cycle Impact Reduction credit Option 2 offers a tiered approach for credit, which rewards teams for assessing the life-cycle impacts of whole buildings. Through Path 1 of Option 2, project teams have the flexibility to choose the level of engagement that aligns with their project goals—such as getting a point just for conducting a whole-building LCA without also demonstrating reductions. This approach has been helpful to project teams that are just starting to dabble in WBLCA, incorporating low carbon materials into standard specifications, and measuring whole-building embodied carbon.

Additional credit is also available in Paths 2-4 of Option 2 for reaching specified levels of whole-building reductions in embodied carbon and other embodied impact areas. This builds on the benefits of WBLCA from Path 1, which can help teams find new reduction pathways. By conducting WBLCA, teams can calculate not only the impact of one-for-one material substitutions but also design strategies like dematerialization and reuse of buildings and assemblies.

How LEED v5 can help

LEED v5 has a prerequisite to mandate entry-level measures for newcomers and a credit to help the industry adopt and improve LCA at scale.

Building reuse and many other prescriptive measures that LEED has incentivized in the past can cut carbon and have other environmental and social co-benefits. They’re also simple, and most don’t come with a cost premium—always a winning way to do the right thing.

That being said, the industry should be ready for a performance-based approach to design and product selection, with new codes across the country and the globe starting to encourage or require WBLCA (take a look back at Section 1 for a list).

LEED v5 is taking steps to align with the legislative movements and benefits of taking an enhanced lens on embodied carbon through the new Assess and Quantify Embodied Carbon prerequisite and Reduce Embodied Carbon credit—with some opportunities for clarification.

The revised LEEDv5 Assess and Quantify Embodied Carbon prerequisite in the Second Public Comment draft is intended to require all project teams to quantify the cradle-to-gate (modules A1 through A3) embodied carbon impacts of the structure, enclosure, and hardscape of a project, then “assess” the largest opportunities for reductions by identifying high-impact materials. With this requirement it seems USGBC is pushing to normalize embodied carbon conversations among integrated design teams. This is all well and good for scaling up adoption of embodied impact thinking, but anyone who has received comments on the Integrated Design credit knows that the subjective nature of the requirement to “describe how project-specific strategies were considered” leaves projects vulnerable to not achieving the prerequisite based on opinion.

The revised LEEDv5 Reduce Embodied Carbon credit in the Second Public Comment draft outlines four possible pathways to reduce embodied carbon emissions. The good news is that project teams may now pursue several pathways simultaneously to show reductions and achieve up to six possible points. Whole-building life-cycle assessment results must now include at minimum all six impact categories to achieve maximum credit, instead of being able to choose any three as seen in LEED v4.1. We are long past the point where any project should get points just by marking up EPDs—a system that causes major documentation headaches anyway. Pilot credit MRpc132, Procurement of Low-Carbon Construction Materials has graduated into a full option in LEED v5’s Reduce Embodied Carbon credit (Option 3).

We trust that the forthcoming LEED v5 reference guide will clarify whether the “top three sources of embodied carbon” refer to material assemblies or to individual products.

It’s interesting that LEED v5 has chosen not to include the full building in the prerequisite. Module D in particular, which covers recycling and recovery at end‐of‐life, is important for understanding the full scope of environmental impacts related to biogenic carbon in biobased materials like mass timber, as well as the recyclability of major impact materials like steel (and even concrete). Module D is currently optional for EPDs in the United States, but is required in the European Union under European Standard BS EN 15804. As mass timber becomes more popular, and focus on recycling structural materials grows, it will be important for LEED to keep up with industry standards as they continue to develop.

3. What baseline should we be comparing against?

A lot has been done to define material benchmarks (aka baseline) in the past several years. Industry-leading benchmarks from the U.S. Environmental Protection Agencay (EPA) and Carbon Leadership Forum (CLF) allow buildings to use the same baseline for material comparison. This may confuse past commitments that self-define a baseline. However, efforts to define whole-building embodied carbon benchmarks and baselines is ongoing.

We don’t have an ASHRAE 90.1 for embodied carbon

Operational energy and carbon have been tracked for decades, enabling project teams to build models and compare them against the average energy use of similar project types, sizes, and occupancy patterns. The rigorous data-gathering and synthesis involved in operational energy modeling have led to the development of standardized tools and processes, resulting in robust codes and voluntary standards thanks to established operational energy baselines by building type.

Embodied carbon modeling has the potential to make an educated impact on the built environment. But like operational energy modeling, it requires time to develop standardized practices that can meaningfully address our collective goal of tackling climate change.

The maturation process experienced by energy modeling over the past decades is ongoing for embodied carbon. Every building is unique, requiring time to understand how embodied carbon relates to design. Consequently, currently there is limited applicability of single whole-building embodied carbon baselines, despite industry efforts to establish embodied carbon targets similar to Energy Use Intensity (EUI).

Nevertheless, industry leaders in the AEC sector, with support from organizations like the Structural Engineering Institute’s SE2050 and CLF, are working to gather the necessary data to establish robust standards. Thanks to these efforts, project teams can take immediate steps to draw down the full spectrum of carbon related to the built environment. Alongside existing tools such as EC3, certification schemes like LEED and LBC, and data sources like Environmental Product Declarations (EPDs), ongoing development of best practice guidance by industry leaders is empowering project teams to participate in the transition.

By measuring the embodied carbon of our projects, being responsible stewards of our data, and sharing that data, we can all champion climate action and accelerate the transition to climate-smart designs.

How LEED v5 can help

LEED v5 should require all projects with WBLCA models to contribute those models to public databases. SHOW ME THE DATA.

USGBC is coming out strong in v5 by requiring material quantification as a prerequisite. Let’s leverage all the hard work of those project teams by compiling the information into massive databases, both for materials and for whole buildings. Efforts are already underway to build databases of building materials data in SE2050 and CLF. LEED’s prerequisite and credit are sure to generate more data, albeit at varying degrees of accuracy.

LEED already requires owners to meter and report ongoing energy and water use during operations. The resulting data is shared anonymously. Why can’t the same logic apply to embodied carbon? There are far fewer barriers to teams contributing upfront life-cycle data since a) they would need to do so as a condition of earning the prerequisite for WBLCA, and b) it would be a one-time requirement.

This is a call to action to work together to get the baseline data needed to establish standards for whole-building embodied carbon. Together, we can get this done as an industry.

4. How can project teams help the industry decarbonize faster?

To navigate this evolving landscape effectively, stakeholders can leverage resources provided by organizations like the Structural Engineering Institute’s SE 2050 and the Carbon Leadership Forum (CLF). These outlets offer both data for material baselines and the opportunity to share data. Project teams can use the former and contribute to the latter.

For use on projects, the SE 2050 offers structural engineers a platform to assess and mitigate embodied carbon in their designs. The SE 2050 Database is a central repository for firms participating in the SE 2050 Commitment Program to submit structural global-warming-potential data. CLF provides valuable data and toolkits for policymakers and practitioners alike. Armed with the latest North American Material Baselines (available in both PDF and Excel formats), industry leaders can more readily set performance targets for their projects, while owners and policy makers can utilize their Resources Library to develop action plans.

Project teams can also participate in expanding the available baseline data through these platforms. Any signatory firm of the SE 2050 can upload data to the Database. This data is used to inform industry benchmarks and targets, ultimately working towards net-zero embodied carbon by 2050. CLF requires teams to reach out to the organization to upload their data. Through the ECHO Project, the nonprofit Building Transparency has published a data schema for reporting whole-building embodied carbon.

Conclusion

Embodied carbon is emerging as a key focus area for sustainability in the building sector. As regulations tighten and awareness grows, stakeholders must embrace the challenge of reducing the environmental impact of construction materials and whole buildings. Through initiatives like LEED, legislative measures, voluntary standards, and industry leadership through groups like SE 2050 and CLF, the built environment can be designed with a more holistic understanding of sustainability—one that encompasses both operational and embodied carbon.

Active participation and knowledge sharing within the industry are crucial for accelerating progress toward climate-smart designs. By utilizing available resources and engaging in collaborative efforts, stakeholders can play a vital role in driving meaningful change and shaping a more sustainable future for the built environment.