I keep seeing references to "commingled recycling facilities must be able to provide project-specific diversion rates or an average diversion rate for the facility that is regulated by the local or state authority." I'm trying to find where that lives officially. I don't see it in the April 5th 2016 "current version" LEED V4 BD&C MR: Const & Demo Waste Mgmt credit description. I looked through the addenda. I am only now getting up to speed on V4, so maybe it's obvious to everyone else... Thank you for any help. I'm also particularly in any info/experience on whether this is being "enforced", if any AHJ's are doing good enforcement of this, etc.

You rely on LEEDuser. Can we rely on you?

LEEDuser is supported by our premium members, not by advertisers.

Hmm. Just to further stoke your interest: I had a person at the USGBC help desk tell me that, since the requirement involved 3 (option 1) or 4 (option 2) waste streams, it means that commingled is no longer allowed. I'm fairly confident that that is not correct, but helps point out why this is sort of important to clarify. In my city, EVERYONE takes this credit currently, virtually all commingled, and NONE of the waste handling facilities that separate on-site are regulated (at least not in the sense that I think would have to pertain: that their facility-level diversion rates are monitored, tracked or regulated in some manner). Of course they have business licenses in their respective jurisdictions I assume, but that doesn't involve any attention to waste-stream recycling rates at all. Note that all commingled recycling in my city goes to neighboring states, so coordinated or harmonized regulation across borders will not be trivial.

Keith - My apologies in replying belatedly. I was on vacation since 9/16 and off-grid until yesterday.

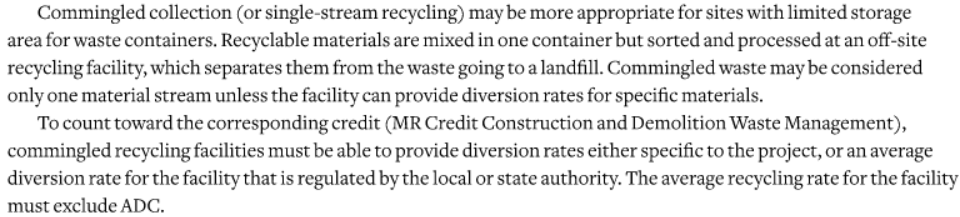

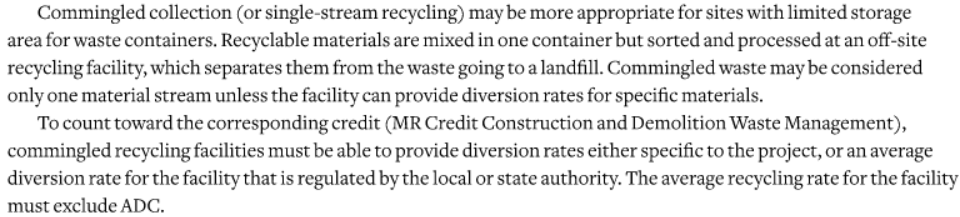

Regarding commingled and your first inquiry, the LEED Reference Guide for Building Design and Construction for LEED v4 (http://www.usgbc.org/resources/leed-reference-guide-building-design-and-...) is the source. Page 480 of the associated prerequisite for this credit (Construction and Demolition Waste Management Planning) states: "To count toward the corresponding credit (MR Credit Construction and Demolition Waste Management),commingled recycling facilities must be able to provide diversion rates either specific to the project, or an average diversion rate for the facility that is regulated by the local or state authority. The average recycling rate for the facility must exclude ADC." (This is reiterated on page 587.) This requirement grew from a previous LEED Interpretation ID #3000 - (http://www.usgbc.org/content/li-3000), which required commingled accountability for LEED v2 and v3 projects registered after 12/2/2005. (This was further refined with LI ID #5171 - http://www.usgbc.org/content/li-5171 from 2009.) Unfortunately I can't speak to enforcement of this by AHJ's but the project's LEED champion should be aware of and enforce this requirement.

Regarding your second post, unfortunately the person you spoke to at the USGBC Help Desk was not well versed in LEED v4 but it would be nice if s/he were familiar with the basic credit requirements. (And frankly, they're not supposed to be technical experts because USGBC has LEED Technical Customer Service for detailed LEED specifics.)

Commingled is definitely allowed. In the case of the associated prerequisite for this credit, the second requirement states: "Specify whether materials will be separated or commingled and describe the diversion strategies planned for the project. Describe where the material will be taken and how the recycling facility will process the material." The person you spoke to may have been confusing the additional information that "Commingled waste may be considered only one material stream unless the facility can provide diversion rates for specific materials."

Am I reading correctly that you think that there is a requirement for recycling facilities that separate on-site to have their values regulated? If so, there is no such requirement because these facilities provide project-specific recycling rates based on the boxes on site.

Note: As a LEEDuser guest, you can't see the Bird's Eye View and other resources above. Becoming a member (http://www.leeduser.com/select) might be something to consider to help in advancing your knowledge of LEED v4.

Thank you Michelle, very helpful!

So facilities that separate onsite per project/load don’t require regulation, which means that no one ever confirms whether they are separating/calculating by load? It would appear that sorting by load can be done visually, which makes it a hopelessly low bar, with no way to confirm. There’s only one facility anywhere near me (large city) that is certified by The Recycling Certification Institute, which as far as I see is the certifying body: do you know if there are other certifying bodies? Am I missing anything? If the certification has to be approved by the AHJ, then is it not reasonable to start from a regulatory presumption: that is, they are considered facility-level certification-required facility until they've proven they aren't? That would at least make some sense, to me...

Keith - Yes to your first question regarding no regulation but I would hope that the project's general contractor and LEED champion are ensuring verification of the calculations. LEED does not allow visual inspections for any waste accounting methodology. (Read the entire thread that starts with this comment in MRc2 in LEED 2009 - http://www.leeduser.com/comment/redirect/61754.)

Second question re: The Recycling Certification Institute - read more at the associated pilot credit related to this - http://www.leeduser.com/credit/NC-2009/MRpc87. The Credit Language tab outlines requirements for certifying bodies. (You could also see this credit in the Pilot Credit Library - http://www.usgbc.org/node/4717858.)I haven't researched this enough to know about other approved providers.

Third question - Yes - I think you are missing information on the pilot credit, which might be adding confusion too. In addition to information above, read this link below - http://www.leeduser.com/comment/redirect/65527.

Last question - Yes to a degree. Your logic makes sense to me regarding some commingled facilities but not facilities that site separate. And remember that commingled collection facilities do NOT have to be certified if the facility documents loads taken from a specific project and do not rely on a regulated average.

Hi Michelle,

How is the average diversion rate for a facility supposed to be regulated/verified by the local or state authority? I am working on a project where the contracted waste receiving facility is claiming that the state of Connecticut offers no mechanism to verify or audit the average facility diversion rate. Instead, they provided a letter stating that the average diversion rate for commingled loads is 65% and that this rate does not include ADC. Is this acceptable?

Risto - Some states do regulate recycling rates based on auditing the facilities. (There's also a pilot credit related to third-party verified rates - https://www.usgbc.org/credits/new-construction-core-and-shell-schools-new-construction-retail-new-construction-commercia-3. Check out the LEEDuser forum - https://leeduser.buildinggreen.com/credit/Pilot-Credits/MRpc87. You might also read - https://www.recyclingcertification.org/certified-facilities/.) If your contracted facility used third-party verification, you might be able to argue this as verified for this credit.

If neither Connecticut nor a local agency offers a mechanism for verification and there's no third party verification, then you need project-specific data. You can't take a letter from the facility as proof.

So, the answer is no.

Thanks, Michelle.

Can you please explain what exactly LEED means by project-specific data? For each load of commingled waste taken to a facility, we get a report showing the tonnage of each material (determined by visual inspection), and a diversion rate based on the ratio of landfilled materials to recycled materials. Is this sufficient?

Thanks

Risto - Visual inspection is never an acceptable LEED methodology for calculating waste amounts. Please read the following posts for more on that and project-specific diversion at: https://leeduser.buildinggreen.com/forum/project-specific-diversion-vs-facility-average-diversion, https://leeduser.buildinggreen.com/forum/volume-measurement, and https://leeduser.buildinggreen.com/forum/reporting-clarification-waste-haulertransfer-station (this URL has a link to multiple items on visual inspection including https://leeduser.buildinggreen.com/forum/alternative-calculation-mrc2, https://leeduser.buildinggreen.com/forum/regulation-commingled-recycling-facilities, and https://leeduser.buildinggreen.com/forum/conformity-commingled-facility-process.

FYI: I found the above links by using the new LEEDuser's powerful Search Forums feature - https://leeduser.buildinggreen.com/forums.

To answer a part of your question, project-specific means each load for that job has backup data as it is disposition. If this and the above previous threads don't help, please post back.

Michelle - thank you for the background information, however, I still don't fully understand what qualifies as project-specific data. If the commingled waste is taken to a facility and they physically separate the materials before weighing, then each material in the load will count as an individual waste stream and 'commingled' waste diversion rates would no longer be of concern. Can you please elaborate on how project-specific data is collected, tracked, and verified?

Risto - It depends on your recycler(s) and how many entities they are dealing with to recycle materials. Each recycler is different. You will need to get verification from each recycling firm you are working with to back up multiple streams.

(From what I am used to with commingled collection and LEED 2009, I would fill out the form using commingled and the overall percentage recycled, which should come from your recycler at the end of the job. But I reviewed the reports monthly, which outlined the boxes/hauls and the volumes or weights of specific materials by load that were recycled and the remaining residual waste. I would then provide final backup from the recycler showing how the overall percentage recycled was obtained (% for metals, % cardboard, % drywall, and % landfilled for example).)

For LEED v4, I still want to see monthly data for projects to ensure we are on track to meet our goals. And to ensure that we are tracking the correct number of streams. (I hope you were able to look at the LEEDuser's Guidance for this credit - https://leeduser.buildinggreen.com/credit/NC-v4/MRc5 and the associated prerequisite - https://leeduser.buildinggreen.com/credit/NC-v4/MRp2). I review these reports and ask questions (verify) if I have any concerns about the data as I get it. The project's specifications should have included development of a CWM Plan and reporting expectations.

If you want to see an example recycling report from a recycler, please use the LEEDuser contact form and send me your e-mail address.

Michelle,

Apologies to keep harping on this, but I still do not understand. What you describe sounds identical to the process I follow to monitor C+D waste diversion during the CA phase. However, I still am not following what the recycler needs to do to verify the percentages of each material obtained are accurate. I have called multiple regional sorting facilities and all of them follow the same process-- commingled waste is brought to the recycling facility, a ticket is issued estimating the material distribution of the load, and mass conversion factors are applied to each material included to generate the reports showing the % of each material received and the % of residual landfilled waste.

Is this the adequate documentation for a project-specific commingled diversion rate under LEED v4? The basis of the rate is still visual inspection, but if the recycler were to separate each material before weighting, then the load each material would be considered its own material stream and a commingled diversion rate would no longer apply. Can you please clarify?

I would be interested to see your example reports to compare against the documentation I typically collect, but I can't find the LEEDUser contact form you're referencing. Can you please send me a link.

Thanks for all the help.

Risto - Maybe we lost the ability to contact each other with the launch of the new LEEDuser last September. (You used to be able to click my name and be able to send me an e-mail.)

I don't think the example reports I have are the "verification reports" that you seek - just summary reports of diverted materials.

Please read my post https://leeduser.buildinggreen.com/forum/volume-measurement#comment-51814 regarding my experience working with a local recycler. They do NOT use visual inspection, which is sounds like what you are facing and is problematic.

I'll get back to you in the next few days with more.

Risto - I wanted to get back to you with more information. Regarding your 5/16/18 post, I was in fact describing the process I monitor waste diversion on a project.

As the LEED project administrator, I personally do not verify what a recycler is doing to verify their percentages are accurate but I do attempt to ensure that they are following a process that meets the letter of LEED.

LEED v4 has similar requirements for commingled waste as LEED 2009 - with one important exception due to the introduction of material streams in v4 (see "Here's the difference..." below). You are supposed to have a measurement (by weight or volume) for individual (and total) materials and visual inspection to determine amounts is not allowed. Yet I recognize (https://leeduser.buildinggreen.com/forum/alternative-calculation-mrc2) that visual inspection is being used in the industry - and gets through a LEED review without being flagged. (Probably because the team is unaware of the situation or that it violates LEED requirements.) This is unfortunate.

Here's the difference: Please note that in LEED v4, commingled waste counts as a single stream if there is not project-specific data. This is extremely problematic for LEED v4 projects because if the majority of your materials are collected commingled you cannot earn MRc5 because you need a minimum of 3 streams. (Some folks have been pushing to get this changed since early 2017 but we've had no success to date. I am hoping others will be posting their thoughts on this situation to "Submit your proposal" on https://new.usgbc.org/leed-v41.)

So, I agree with your assertion that if the recycler were to separate each material before weighing each material would be considered its own stream. That's what you want. Otherwise you can't earn the credit. Since the current version of the Construction and Demolition Waste Calculator - - doesn't count multiple streams if you use "Commingled - recycled" from the Material Stream dropdown. I would use Other (specify) and put "Commingled - Project-Specific" and then you get credit for the separated streams. But I would include the reports from my recycler as the LEED reviewer will hopefully connect that a project says they are collecting materials commingled in the CWM Plan but not showing "Commingled - Recycled" in the calculator. (The MRc5 form asks for this data for commingled projects.)

So to answer your question, yes - if you get project-specific reports outlining the amount of material that is diverted and where, it should be adequate for LEED v4.

If you still want to see an example report from a certified LEED 2009 project, please use Earthly Ideas' contact form - http://www.earthly-ideas.com/contact.htm - and provide your e-mail address so I can send it to you.

The alternative approach to relying on a facility to accurately separate and report a commingled stream could be to separate on-site for select materials, correct?

We have a CI project we're actively certifying that, like most projects, isn't able to get the specific breakdown info required to count commingled as multiple streams. I anticipate this will also be the problem with my other CS and NC projects that just haven't gotten that far yet. For the CI project, we had regular commingled as the first stream, then tracked the demo (which happened to be minimal and only metal) as a stream, donated furniture as one, cardboard/paper from all of the furniture and such (what wasn't wrapped in blankets) as one (made the furniture vendor track it), and wood as one. We also had very limited space on-site to have separate bins (very large, multi-tenant building in an urban core), so all of our streams were things that occurred as separate actions, if that makes sense; they were not separated by the regular waste hauler. We looked into working with a takeback program for ceiling tiles and/or carpet, but with very limited demo, didn't have enough from install scraps to justify the effort. Those were going to be our alternatives, though, and the only other way we could figure out to have separate streams and earn the credit.

Emily - Thanks for sharing your real world experience!

Yes, you are correct regarding source (on-site) separation. The challenge I've been facing is where the only local recycling service available provides commingled collection, and the project is a new building (no demo) pursuing LEED BD+C: NC. Hence there are not distinct phases like you had for your CI project, and we've basically got a single stream of commingled. Luckily for my local projects, the recycling firm provides project-specific data that allows us to count the commingled waste as multiple streams under LEED v4.

Other recycling firms don’t provide their data that way. Hence those projects are stuck with a single stream for LEED v4. (I'm still hopeful this will change under LEED v4.1.)

Lastly, I wanted to wrap up an item that Risto and I discussed. Paula Melton shared with me that we did lose the capability to contact each other via LEEDuser when the site relaunched in September 2017. “Apparently it will be coming back, but it’s on the back burner at the moment.”

I have a question regarding the using the facility's average diversion rate.

I understand that projects can use facility's average diversion rate which is regulated by the local or state authority . However, I am not clear on the other requirement that the reference guide states regarding " This system must be a closed system;shipping waste to another municipality to manage, thus burdening another system, does not count as diverting the waste."

Does this mean that the project site,waste sorting facility and the end user recycling facility must all be in the same municipality (city, town) ? If yes,is this a requirement or a recommendation ?

Meghana - The information you have quoted is new to LEED v4, and it might be something that LEED v4.1 should clarify so we are ensured of the intent because it is written rather narrowly.

My interpretation is that the project site, sorting facility, and the end user recycling facility do not have be in the same municipality. That's totally impractical. I think they are trying to say that if you are using a facility's average diversion rate you can't say the facility is sending its waste to another municipality to handle - as USGBC would not know how or if it will be recycled there. If companies were to do that, the waste could be landfilled and not diverted. I think they are trying to get teams to fully understand where the ultimate recycling facility is in order that we have confidence in the disposition and true diversion of materials for teams using a facility's average diversion rate for commingled waste.

If your situation is that you are using a facility’s average diversion rate, then I would ensure you have a good understanding of how they handle the waste that leaves that facility so you can confidently say it was diverted.

(P.S. My experience has been that we are required to follow the credit's requirements in our pursuit of credits. Items that are in the Reference Guide are good resources and recommendations. Yet sometimes the information can be contradictory; however, at other times, LEED reviewers quote information in the Reference Guide as though they are requirements. My philosophy has been - if it's in the Reference Guide, it's best to make sure you can back up your claims to meet what is in there.

FYI: The Reference Guide Overview in the v4 Reference Guide states: "STEP-BY-STEP GUIDANCE suggests the implementation and documentation steps that can be used by most projects, as well as generally applicable tips and examples." The Getting Started - How to Use This Reference Guide section states: "This reference guide is designed to elaborate upon and work in conjunction with the rating system. Written by expert users of LEED, it serves as a roadmap, describing the steps for meeting and documenting credit requirements and offering advice on best practices.")

Thanks Michelle for your quick response and clarification on recycling facility requirements !

I know I'm jumping into this long chain, but I am trying to understand if I have project-specific diversion rates for commingled recycling, can I count them as separate waste streams to achieve the credit? How do I arrive at a project-specific diversion rate if I have paper, metal, and wood commingled in a recycling bin? If I have separate bins on-site for these three materials, receive weights of each of them, does that allow me to deem it "project-specific" even if it goes to the same commingled recycling facility?

Hi Kristin - Here are answers to your questions in order:

- Yes.

- Your recycling provider will need to provide details on the amount of each material (either by weight or volume) that was recycled from each commingled load taken from your job. Adding all these loads up will give you the project-specific diversion rate for your job.

- You are comparing apples to oranges here - collection type vs. facility type. If your job provides separate bins then you are using on-site separation. Your recycling provider will need to provide you separate waste stream amount information for each stream for each load - even if it goes to a commingled recycling facility. LEED assumes that projects using on-site separation collection get "project-specific" information for each stream as the term "project-specific" is really applied (for LEED) to the method of on-site commingled collection.

Thank you for the response! I was looking at the excel spreadsheet for the credit and the language in the RG had confused me on how I could get commingled recycling to count as multiple waste streams! I have a project with limited opportunities for reuse, salvaging, or donating so I was hoping to hit the waste stream requirement through commingled recycling! I'm having a conversation with the recycling facility next week and wanted to understand if it had to be project-specific diversion rates to count towards multiple material streams, or if a recycling facility average diversion rate would suffice. I'll stress the need of project-specific. Thank you!

I'm back and with a follow-up question! If I have commingled recycling and I'm only going to count it as ONE material stream (different than my previous question), do I need to have state/local average diversion rates excluding ADC? Or if I'm just counting commingled recycling as ONE material stream, do I lose the requirement for diversion rates all together? Thank you!

Hi Kristin - The challenge I've noted with counting commingled recycling as a single material stream is that Option 1 of MRc5 requires three (Path 1) or four (Path 2) material streams. The Reference Guide notes: "As a best practice, a material stream should constitute at least 5% (by weight or volume) of total diverted materials." Some projects won't have enough compliant streams to meet Path 1 if commingled is one stream. If you're following Option 2 (or just pursuing the prerequisite (MRp2)), it's not an issue.

Commingled diversion must be reported as either project-specific or the facility diversion rate. Typically project-specific commingled info can be further broken down into specific material streams, which then allows Option 1 achievement.

To answer your questions:

- If you are just going to get project-specific commingled info (as a single stream), then no - you do not need state/local average diversion rates.

- I'm not sure what you mean by losing the requirement for diversion rates. Do mean following Option 2? Or do you mean establishing diversion goals in the prerequisite (MRp2)? Commingled waste that is diverted from the landfill would still be used to calculate your project-wide diversion rate for MRp2. And even if you are not pursuing MRc5, you still have to do everything in the prerequisite.

Hi Michelle,

Thanks for the response! I will only have commingled for paper, cardboard, and plastic on the project. Metal, concrete, and asphalt are being recycled separately by themselves hopefully qualifying as a single material stream each (for a total of three). If I want to count the commingled as my hopeful 4th material stream, do I need to provide any information on diversion rates (project-specific or facility average)? I am currently reviewing this with the CM on the project. They are interpreting the LEED RG that I don't need any information if I'm just counting my commingled as ONE material stream. I'm not reading the RG that way, so I'm reaching out here to confirm who might be reading this right!

Kristin

Kristin

Hi Kristin - If I'm understanding you correctly... I think your interpretation of the Reference Guide is correct. If you don't have the amount of the commingled waste that is diverted, you won't be able to count the stream's contribution to the overall diversion rate for Path 2, which requires at least 4 streams. Without a diversion amount, the value of the waste would have to be included in the landfilled material instead.

I'd encourage you to point out Equation 1. Diversion Rate and share the Construction and Demolition Waste Calculator - https://www.usgbc.org/resources/construction-and-demolition-waste-calculator with them to illustrate the need for the amount of waste diverted. Good luck!

Hi Michelle,

Appreciate all your help, but I'm not sure I'm following still unfortunately. I still am not clear on what the requirements are for the CWM credit if I want to count commingled recycling as ONE material stream. The confusion comes from the following language:

Prerequisite: "Commingled waste may be considered only one material stream unless the facility can provide diversion rates for specific materials. To count toward the corresponding credit, commingled recycling facilities must be able to provide diversion rates either specific to the project, or an average rate for the facility that is regulated by the local or state authority."

Credit: "To contribute to this credit, commingled waste diversion must comply with one of the following requirements: 1) Waste-sorting facility provides a waste diversion specific to the project's waste... visual inspection is not an acceptable method of evaluation for documenting this percentage. 2) Project team uses the facility's average diversion rate, which must be regulated by the local or state authority..."

My question still remains, what do I need to have to count commingled recycling as ONE material stream? Do I just need a letter from the recycling facility? Do I need some form of a diversion rate? Or am I making this harder than it needs to be?!

Thank you!

Kristin

Kristin

Kristin - Yes - you need one or the other type of diversion rate. (And yes - I think you are making this harder than it needs to be. ;))

Just like any other construction waste material, you need the volume or weight of the commingled material to calculate the overall diversion rate for the project.

If your vendor's facility does not have a facility average diversion rate for its commingled waste, you need the volume or weight of the diverted commingled material for the project you are working on (project-specific).

I think the two quotes above are saying the same thing. They are trying to say that without project-specific data, you can only count commingled waste as one stream. Since you only want to count the waste as one stream, you still need data on the commingled diversion rate, which would be project-specific since you do not have facility average diversion rate. You should also provide backup as to what your commingled waste stream includes and note those materials in the Material Description column in the Construction and Demolition Waste Management Calculator.

If this is still not clear, please visit http://www.earthly-ideas.com/contact.htm and get EI's phone number to call me.

Hi Kristin,

I agree with Michelle that the two quotes are saying the same thing, essentially. I will add that for prerequisite compliance you need to provide the plan and your total diversion rate (with total waste and total diverted identified), but the credit requires the specific documentation and proof of your diversion with materials noted. If you are noting "commingling" as one waste stream, then you need either the project-specific diversion with documentation, or the facility's average diversion rate. The project-specific diversion documentation has to identify the breakout of materials, although it is commingled onsite.

Our experience has been in both v2009 and v4 that you cannot simply have the line item of "commingled" with a diversion rate, unless you are using documented proof of the facility's average rate. As not all facilities have this currently, breaking out what materials are included in the "commingled" category is important. And, this is the breakdown you need to provide as proof of actual diversion if going the project-specific route.

Thank you, Michelle and Tiffany! This has confirmed what we need. I have been reviewing this with our CM, and their LEED expert and I have been disagreeing on how we need to approach this. I appreciate your assistance!

Kristin

Kristin

Hi Michelle,

My issues surrounding this credit still have not been resolved and the recent discussion has only convoluted things. This credit has been problematic for every one of my firm's v4 projects where site separation is not possible due to space/budget constraints. The issue boils down to the fact that we have not been able to find a single waste receiving facility that processes commingled loads in the way you are describing.

You stated that, "Luckily for my local projects, the recycling firm provides project-specific data that allows us to count the commingled waste as multiple streams under LEED v4", but how exactly is your recycling firm determining their project-specific commingled diversion rates? If you could provide me with the contact information for your recycler, I would be very interested to call them to discuss how they are achieving this.

I have contacted all major waste haulers surrounding New York City, Philadelphia, Boston, and New Haven, and all facilities still use visual inspection to determine the "project-specific commingled recycling rate". Even those facilities that have been certified with the RCI, and are on the leading edge of sustainable waste management, follow this procedure and have stated that this is the standard practice across the industry. The steps involved in this process are as follows:

- Contractor sends load of commingled waste to the receiving facility

- Waste receiving facility weighs the entire load

- Percentages of materials are estimated and recorded (x% wood, x% metal, etc.)

- Volume to weight conversion factors are applied to each material in the stream to determine the mass of each material in the commingled load (x tons wood, x tons metal, etc.)

- Commingled waste is processed through the sorting machine that separates each material into the appropriate bin for recycling

Risto - I sent Michelle almost the exact same message via email and pulled out her same quote. All of the Massachusetts, Rhode Island, New Hampshire, Connecticut, etc. facilities use visual inspection for project-specific data (or just apply their annual rates to each dumpster as if they all have the same mix of materials). I know lots of projects are submitting this and getting it accepted, but the USGBC has indicated it is not supposed to be allowed. I can't imagine weighing each of the small, separated piles from a given dumpster would ever happen or that we'd want to encourage such inefficiencies, but that is what the USGBC is requesting.

Risto -

I have reached out to the local independent small company that I was discussing above to ask about you contacting them. In the meantime, to answer a few of your specific questions based on this vendor's previous processing facility (as I understand it) from working with the vendor and visiting the facility:

I have reached out to the local independent small company that I was discussing above to ask about you contacting them. In the meantime, to answer a few of your specific questions based on this vendor's previous processing facility (as I understand it) from working with the vendor and visiting the facility:

- Their previous facility did not have a conveyor system so they sorted materials on a large processing floor and put them into containers.

- They only used 30 cubic yard roll-off boxes.

- They processed each LEED job's boxes apart from other job's boxes. Hence, they stockpiled boxes for a specific LEED job and then processed the materials all at one time. They did this in intervals throughout the project (~monthly) to not have too many boxes tied up at one time. (This is the project-specific aspect.)

- They did not use weight as they did not have a scale. They used volume as their metric and converted each individual material's total volume to weight but they provided both weight and volume values in their spreadsheet backup so teams could choose whether to use weight or volume. In my experience, weight always provided a larger overall diversion percentage than volume - due to heavy materials like brick and block.

Hi Risto and Nathan,

What you both are describing is what we experience too. There is a disconnect between what LEED requires and what industry is capable of presently. Ultimately, LEED v4 is aimed at pushing the limits and reaching above and beyond. What we find is that industry still has a lot of catch up to do with many of the credits within LEED v4. We see this with the product declarations as well. I can appreciate the depths you have gone to understand what the haulers are doing and how they are calculating the diversions. It is certainly frustrating if you are finding that they are not quite at the point of weighing and separating as LEED would like and what is required from a LEED standpoint. Ultimately, it comes down to the documentation that you are given from the hauler and what their practices are. As a recognized hauler and waster/recycling provider, they are held to likely state mandates that require certain separation practices. I have not yet had a review come back questioning how the diversions were calculated, although not out of the realm of possibility. As long as the hauler's documentation and tickets indicate what materials and quantities were removed and where it went, if at a project-specific level, then I truly believe that can be relied upon from a documentation standpoint.

In answer to your question on how project-specific and facility average diversion rates are different after commingled is separated, nearly all of our projects are able to calculate a higher diversion at the project level because of the site setup, training, management, and policies in place at the project level. We haven't yet seen a facility average be higher than our site specifically, so it can be advantageous to document using project-specific.

Michelle,

It sounds like you have found an exception to the industry norm, but the method you've described would not be possible for the scale of projects I am involved with (some exceeding 1,000,000 ft²). I feel that I have no choice other than to follow Nathan's recommendation and submit the visually-inspected diversion rate as the project-specific diversion rate and hope the USGBC accepts it.

For the project you are referencing, how are you inputting the separated waste streams into the LEED v4 CWM Calculator? If a commingled load came in to your facility with concrete, wood, and steel, would you mark the material stream for each type of material as "Commingled - Recycled" or "Recycled - Source separated"?

Risto - I agree that this small independent vendor's methods cannot be applied to larger projects/operations.

I also agree with your and Nathan's assessment/investigation of the industry and the need to use the data that has been presented to you by these vendors for your LEED documentation. From this LEEDuser discussion forum and others, other correspondence, and additional research, it is apparent that visual inspection is used widely in the industry - despite USGBC's assertion that it is not acceptable.

I continue to hope that the USGBC MR TAG will be mining forums like this in order to address disconnects between reality and LEED in LEED v4.1. (But I also know we have to continue to create tension to get the market to change.)

To answer your questions about documentation, I plan to select "Other (specify)" from the Material Stream column dropdown and type in "Commingled - project-specific" to key in the reviewer that we are presenting project-specific commingled data.

Lastly, I applaud you asking questions, not taking information at face value, and working to improve the industry!!

Hi all,

I share the expressed frustration, and it is now compounded by my receivers telling me that other LEED projects are getting credits approved using a visual inspection methodology. So my projects get penalized if I take a stand on this issue!!! To be fair, this is not necessarily apparent to reviewers. If you receive visual information and then provide it to reviewers as tonnage that is source separated, no backup is needed and you are presenting it as separated tonnage. They would have no way of knowing it's actually based on a visual inspection.

Michelle, you are a terrific resource and have been very patiently trying to mediate a difficult situation. Thank you.

But as we've discussed before, if you use a volume measurement approach and then convert that volume measurement into tonnage, you are in effect taking a visual metric and then turning it into tonnage and reporting it to reviewers as source separated tonnage. The result is the same outcome of starting with a visual basis and then showing reviewers tonnage. Please note that there is no guidance on volume measurement to suggest there is anything wrong with this approach. It does however seem to help obscure the issue.

I agree that volume is a visual measurement (or a visual metric) when you use a pile of material to approximate the volume. However, in the scenarios I have described on this and other forums, the local vendor's process that I referenced used specific boxes of various volumes to arrive at the volume. They did not put items in piles and visually estimate the volume. The material had to be put into containers to be taken to the end recycler and a volume of material was evident when material was put into said containers. The owner wrote to me: "When you have a container of just one item, it's pretty easy to tell how much is in there." But there was a human estimating if an X cubic yard container was full or 1/2 full.

I recognize that the scenario I described is a labor-intensive process but it was created and followed in order to provide detailed and accurate information for LEED documentation. This was not done for other recycling efforts at this facility as there was no need to quantify the material to this level - it just had to be sorted and then delivered to the end recycler.

I feel confident that the LEED requirement to not allow visual inspection was to avoid an ambiguity and prevent corruption but as this forum and other threads have presented, the requirement is not in touch with reality.

I would encourage those of you engaged in this issue to (continue) to contact USGBC with your concerns about the disconnect between reality and LEED. One way would be via LEED v4.1 by visiting https://new.usgbc.org/leed-v41 and click on submit your proposal.

I will wrap up my comments on this topic by saying that the vendor I work with recently built a more automated facility with conveyor belts, which is safer for the workers, cleaner, and more efficient for processing material. It's better in nearly all ways - with LEED sorting being the big exception. The owner wrote to me that the big challenge "is that it is VERY hard to measure things after they have been sorted with any kind of an automated system." So, I will feel your pain up close and personal on my next local LEED project...

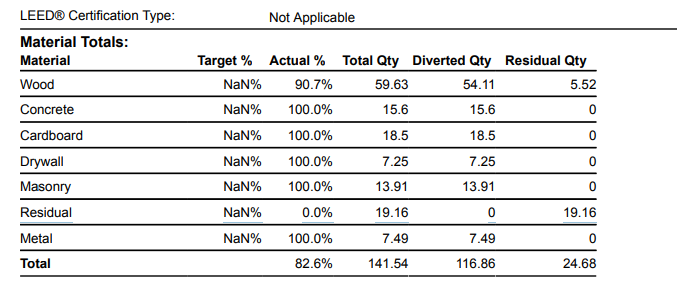

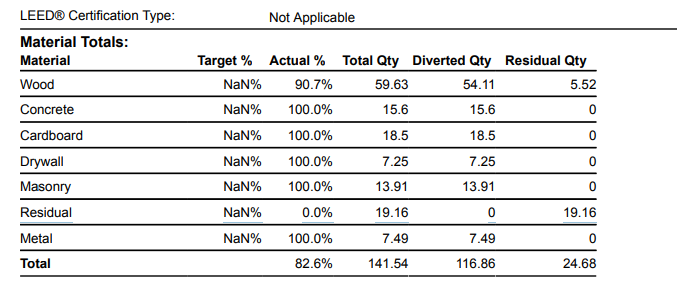

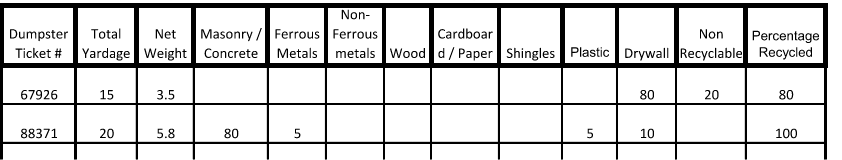

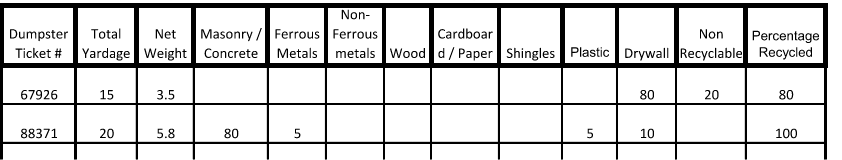

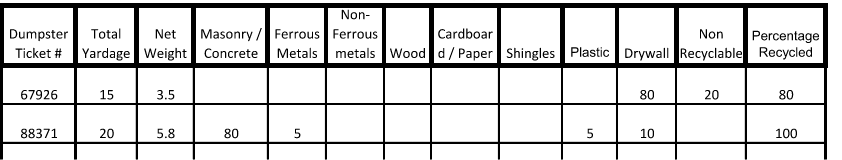

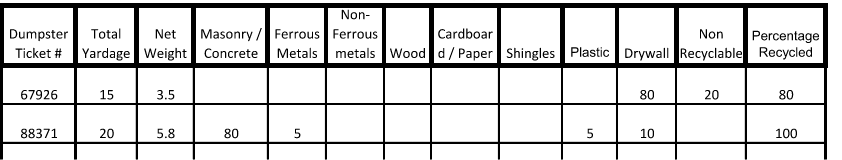

Hello,I came across this post as I am working on a project that is going for LEED V4 certification. I am also not too sure about the commingled waste and the following quote "Commingled waste may be considered only one material stream unless the facility can provide diversion rates for specific materials." I was hoping that the commingle waste could count as multi material stream as long as that could be documented by the sorting facility. For example if my commingled waste consists of drywall, metal and wood and the facility that separates it can document it, then those materials can count as separate waste streams. For example this is a sample summery the facility was able to provide. Additionally if my Concrete was the only material in the container and went to the same facility, what proof do I need to document it, to demonstrate that it was a different material stream?

Hi Magdalena, the reason counting comingled loads for multiple material streams is NOT allowed is that commingled loads are visually estimated to justify the breakdown of that specific load, and there is no realistic accountability for underestimating the residual. Also, materials lose additional recyclability as they go through a sorting line. The only way this would be allowed is if individual loads are manually sorted (pre-sorting line) and then weighed individually, which would never realistically happen unless maybe it was a small negative sort to remove contamination from and otherwise uniform load. Otherwise, ONLY uniform loads may be documented as close to 100% diverted, and all comingled loads must use the sorting facility-wide average. Once LEEDv5 comes out, that facility-wide average is capped at 35% unless they have 3rd party verification. Please note there are still cheaters out there, even among the Sustainability professionals community - don't mistake what's typical for what's right.

Below is from page 492 of the v4 reference guide. The key is that visual inspection is NOT considered load-specific diversion rates. Visual inspection has actually NEVER been allowed, as far back as 2009 (but unfortunately people have cheated and it's gone unenforced)usgbc.org/leedaddenda/2383 and also 5157Page 492 of v4 BD+C reference guide:

Hi all,This is a very old stream and apologies for not reading every post. I have been a LEED consultant for 19 years in a region with robust recycling facilities. Even in our area, visual inspection has been a standard for many facilities and I have spent untold hours educating folks about the commingled sorting process which piles everyone's loads in the middle of the yard and then sorts and weighs those sorted materials at the end of the month. Nobody is getting project specific tons out of this process because every project's recyclables are getting commingled together. In that scenario, being able to use a monthly facility diversion rate has been a god send. Having said that, I agree with Geoffrey. Lots of folks are confused by this in the field and even amongst the LEED reviewers. LEED certification has always been based on intent, and whether the project is trying to do the right thing or not. That is not the same as figuring out how to document something in a way that will get the points regardless of how the issue was handled by the team. Our recycling industry has tanked in the last year and those 2pts that we have been able to rely on for more than 10 years are no longer achievable so we look elsewhere. Some projects are too tight for space to have multiple bins and source separate. Some projects don't have demolition to produce more waste streams. If the project can't achieve the credit, then the LEED consultant shouldn't recommend them and the team shouldn't expect to get those points.

Amen Michelle! Just because there's a hardship doesn't mean we give projects free passes for not doing what others go out of their way to do. To make it even MORE confusing, even though visuals can't be used to officially justify diversion rates, we STILL gather the visual breakdowns because it has SEPARATE value in simply having a rough idea of the relative breakdown of material streams. It's kinda like how your credit card gives you a breakdown of your spend, and you know it's not 100% accurate based on their categorization, but it's close enough to get a rough idea (I spent WHAT on on-line merchants?!?!?), but it doesn't change the fact that you still have to pay it all off! But I think this also inherently confuses facilities when we say "we still want to see visuals" they forget that it has to be in addition the average rates, and it's two very different datasets in parallel, and unfortunately people get confused and just run with the higher numbers...

Hi Geoffrey and Michelle, Thanks for you input. I greatly appreciate it. With what I read, it would mean I only have 3 waste streams, concrete from the site demolition, asphalt from the site demolition and commingled from existing and future building. (the chart below shows the commingled) Hmm... so when the hauler provides me with the breakdown of percentages it doesn't mean it's true, and this is just visual inspection ?

Hi Geoffrey and Michelle, Thanks for you input. I greatly appreciate it. With what I read, it would mean I only have 3 waste streams, concrete from the site demolition, asphalt from the site demolition and commingled from existing and future building. (the chart below shows the commingled) Hmm... so when the hauler provides me with the breakdown of percentages it doesn't mean it's true, and this is just a visual inspection ?

Yes, Magdalena. That's it exactly. The monthly diversion rate document may look similar to this table but all you will be taking from that facility report will be the bottom line percentage they are declaring for the month to use in your calculator for that commingled month of waste. It's a tough area and confusing. You are on the right track. Good luck and have a good weekend.

Hi Michelle,Thank you, and yes all this is confusing. When you say "monthly diversion rate document" do you mean one from the facility or from the hauler? Michelle if I decided that in the end of construction I'll add a container only for cardboard, can this count as 4th material source, even if the hauler will take it to the same facility as the comingled waste?

Hi Magdalena,I mean the monthly diversion rate document from the receiving facility which you may have to request through the hauler. And yes cardboard can be the fourth waste stream along with concrete, asphalt and commingled.

- Ok, I understand that part. Thank you.

- I am also looking at the post that Kristin wrote, and also someone else told me that if my facility can confirm they sort and weigh my individual loads, not using a facility average, then that is sufficient. If I can confirm that what they gave me in the spreadsheet was sorted and weighted as individual loads then I can say my materials are separate streams. Correct?

- When it comes to Waste Management Plan, can I have both options commingled and source separated mentioned there but lean for all source separated under Expected Waste Streams & Disposal Procedures, or do I have to stick to one from the beginning. This is when for example my facility will be able to provide the backup. Do I just have to ask in advance. How would I state that in my plan.

Hi Magdalena,How would you confirm the receiving facility sorts and weighs your individual loads? Perhaps there are facilities that pursue a different approach to this but in the industry as I have experienced it that would be incredibly rare. They would have to stop what they are doing when your load arrives. Have space in the yard to dump just that truck. Employ their sorting methodology for just your truck. Carefully weigh each different sorted pile and report that. And then go back to what they were doing. Unless they are charging your project a lot more money, I am not sure why they would do that.I think you are overthinking this whole thing. Yes you can have source separated and commingled in your plan. Everyone typically does. What heading you use is your business. Just identify the waste streams and the receivers and how much of each you anticipate.If your concern is that the majority of your construction waste is going to be commingled and that the percentages you get from the facility will be too low to make 50% diversion for 1pt under v4.1, then all you can do is stress the importance of the demolition and source separating on-site by the contractor as much as possible. That's it. That is why you have to plan a point buffer. Not everything works out in the project's favor.

Hi Michelle,Yes, I think I am too worried about this. The project is registered under V4 and is striving for 2 points under this credit. From what I have so far, with proper documentation, I can achieve 1 point already. Correct?If I go for the second point, I think I can try cardboard and maybe metal as the additional 2 and the commingled, which I already have, and what we talked about. I think I am spending way too much time figuring this out because I am used to v2009, where you could get those points without worrying about the waste streams, maybe that's why I get tricked thinking about this. On a different note, are we allowed to use v4.1 just for this particular credit, or would the whole project need to be registered as 4.1?

Pagination

Add new comment

To post a comment, you need to register for a LEEDuser Basic membership (free) or login to your existing profile.