Like the other two Building Product Disclosure & Optimization (BPDO) credits, this one has a point for transparency, and one for optimization. Unlike the other two, however, the transparency point here is the hard one (essentially unachievable, in fact) because the building products industry lacks a system for reporting on the raw material extraction impacts of products.

The optimization point, on the other hand, is relatively easy because it uses attributes from past versions of LEED that are well-established in the industry.

Option 1: Don’t bother collecting corporate sustainability reports

Many LEED project teams fail to read the credit requirements carefully and spend time collecting corporate sustainability reports for the products they’ve specified, only to have this point rejected by GBCI reviewers. That’s because hardly any corporate sustainability reports meet the requirements.

You can look for reports that do comply if you like, but it’s very unlikely that you’ll find enough of them. Your best bet is with materials purchased directly—or almost directly—from the company that mines or harvests them, like rough lumber or stone. As soon as materials get mixed up in complex a manufacturing supply chain, there is almost no chance that corporate reports will comply.

For a corporate sustainability report to allow a product to count towards the point, at least 90% of the contents of the product has to be made from raw materials that are covered by the report (no partial credit for products that don’t meet this threshold). In addition to meeting the requirements of the Global Reporting Initiative (GRI), or one of the other listed frameworks, the report or reports have to include this information about the raw materials:

- Where the raw materials were extracted,

- The supplier’s long-term commitment to ecologically responsible land use

- The supplier’s commitment to reducing environmental harms from extraction and/or manufacturing processes, and

- The supplier’s commitment to meeting applicable standards or voluntary programs that address responsible sourcing criteria.

GBCI will look for all of this information about those raw materials highlighted on the reports.

Option 1: A more promising path

A more promising path—although still too limited to be worth pursuing in most cases—is with approved certifications programs for raw materials extraction. For example, USGBC’s LEED Interpretation #10455 endorses ANSI/NSF 373 Sustainable Production of Natural Dimension Stone as a “USGBC-approved program.” Material extracted in a way that conforms with this standard counts as third party verification (full credit) if the stone facility has earned certification, made its scorecard publicly available, and earned either credit 7.2.1 or 7.2.2.

Option 2: Recycled Content, Certified Wood, and More

Option 2 references Forest Stewardship Council (FSC) certification, materials reuse, and recycled content without notable changes from past versions of LEED. There are three big changes from LEED 2009, however:

- A new option: extended producer responsibility (EPR), or product “take-back” programs

- A major new constraint on non-wood biobased materials: they have to meet the Sustainable Agriculture Network (SAN) certification requirements.

- A new “Legal Wood” pilot credit that, in effect, allows many other forest certification programs to count alongside FSC.

You can mix and match products that meet any of these criteria to get to the threshold of 25% of material (by cost), and you can even double count products that meet more than one criterion—just don’t try to double-count FSC-certified recycled content as FSC-certified wood.

Sustainable Agriculture

Sustainable Agriculture Network (SAN) certification was introduced to certify biobased materials that may not fall under the wood or bamboo category, such as cotton, wool, straw, soy, or corn-based polymers. As an program of the Rainforest Alliance, the SAN standard ensures that crops are responsibly sourced according to ten categories, including everything from wildlife protection to occupational health.

SAN certification by the Rainforest Alliance could bring more rigor to an area in which anything with an agricultural basis has passed as “green.” However, very few products are actually certified under this program, and no other programs have been approved as equivalent. As a stopgap, LEED allows project teams to include products with "manufacturer-declared conformance" to SAN (except for bamboo and non-wood forest products that could be FSC-certified). Products must meet these conditions, according to the Reference Guide:

- The product’s manufacturer provides a signed letter on company letterhead from the raw material supplier attesting that its practices meet the standard.

- The letter includes a link to a publicly available document that specifies how the raw material supplier’s practices conform to each paragraph in all 10 sections of the standard and attesting that each “critical criterion” is met.

- Both the letter and the detailed documentation are dated within one year before the date of project registration.

Extended Producer Responsibility (EPR)

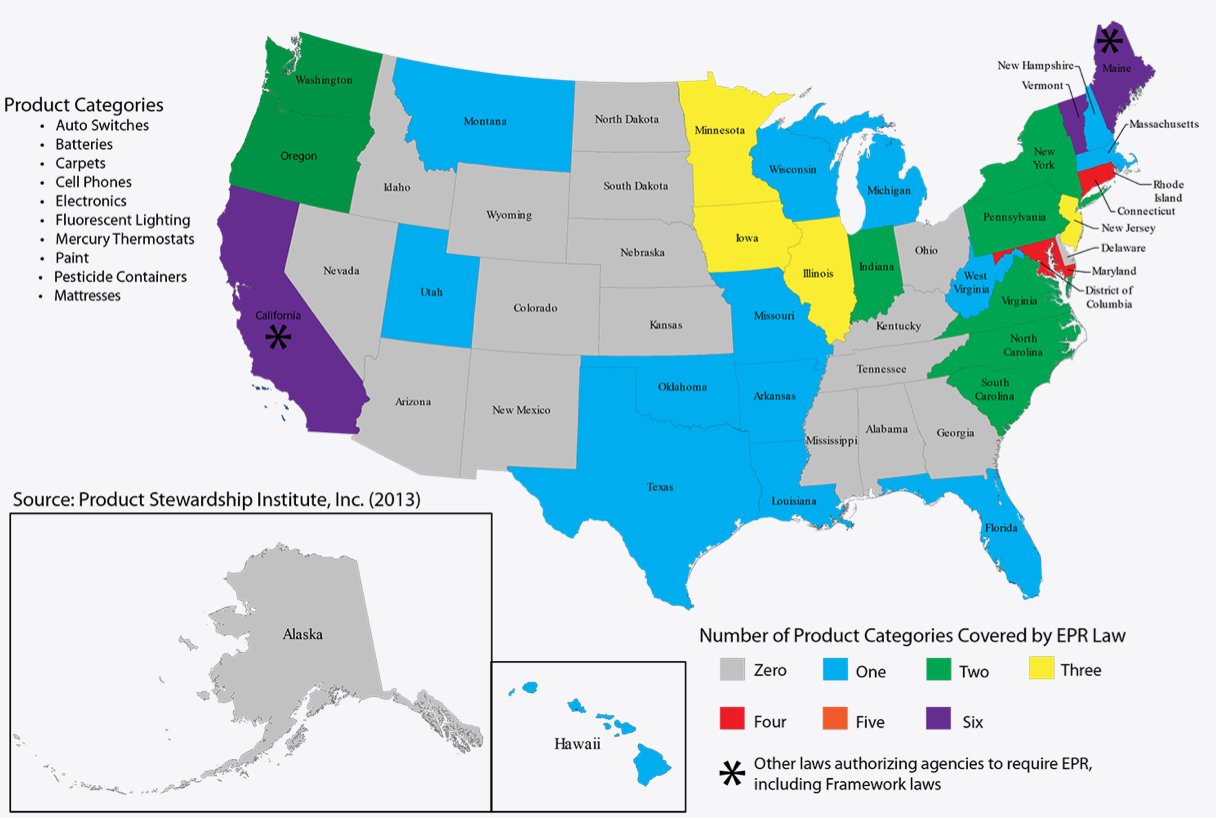

Better known as “product take-back,” EPR means that a manufacturer has set up systems to reclaim its products at the end of their useful life and to recycle them into the same product in a “closed loop,” or to otherwise dispose of them safely and in the most productive way.

It has become common to see building products advertised as “recyclable,” but some manufacturers have stretched that term to the limit, using it as a label for new product lines for which established, closed-loop recycling processes haven’t made it out of research and development. LEED v4 requires compliant EPR products to be have established programs that include program literature and contact information.

It has become common to see building products advertised as “recyclable,” but some manufacturers have stretched that term to the limit, using it as a label for new product lines for which established, closed-loop recycling processes haven’t made it out of research and development. LEED v4 requires compliant EPR products to be have established programs that include program literature and contact information.

LEED allows for EPR programs that are run by other organizations, so it’s not necessary that each manufacturer have its own take-back program. But any independent initiative has to have documentation that the materials it is “taking back” are actually being recycled at a high rate.

The Legal Wood Pilot Credit

Depending on whom you ask, this 2016 pilot credit is either an attempt to test out a potential future prerequisite that would prevent LEED projects from using illegally harvested wood, or a back-door into LEED for timber that is certified under programs that the wood products industry prefers instead of FSC.

In effect, it’s both.

Unlike many pilot credits, that are basically pre-approved innovation points, this one is an “alternative compliance path” (ACP). That means that rather than using up one of a LEED project’s limited Innovation points, it’s an alternate route to earning the Option 2 point under this credit. All the requirements for this alternate route are identical to those in Option 2, except for the FSC pathway.

Instead of only allowing wood that is FSC certified to count, this ACP endorses any forest certification program that meets the requirements of ASTM D7612-10, “Standard Practice for Categorizing Wood and Wood-Based Products According to Their Fiber Sources,” as long as the project’s wood products also meet two other requirements:

- All wood has to pass a basic screen for risk of illegal harvesting, and provide additional documentation if it isn’t low risk; and

- At least 70% (by cost) of the wood has to meet the ASTM’s standard for “wood from responsible sources.”

Other certification programs (in addition to FSC) specifically cited in the appendix to the standard are:

- Sustainable Forestry Initiative (SFI)

- American Tree Farm System (ATFS)

- Programme for the Endorsement of Forest Certification schemes (PEFC), and

- Canadian Standards Association Sustainable Forest Management Standard Z-809 (CSA-SFM)

Finding LEED-compliant products

As explained above, LEEDuser's recommendation for seeking out products that comply with Option 1 is simple: don’t bother. There just aren’t enough products out there with corporate sustainability reports that meet the LEED requirements.

If you’re using a lot of materials in their natural form, however, such as natural stone, you can check out the NSF Directory of products certified under NSF 373. Be sure to confirm with each manufacturer that they earned one of the points under section 7.2, however—that information isn’t listed on the NSF website.

For Option 2, the products you need can be found it different places for each attribute.

Extended producer responsibility (EPR): EPR is fairly common in carpeting, and some companies in other industries are advertising LEED compliance. However, most EPR programs are in response to state regulations for products with concentrated toxic content like mobile phones and fluorescent lamps, and aren't likely to contribute very much to the cost basis required for earning this credit. Paint is an exception—in some places used paint collection programs can qualify. Note, however, that products meeting the EPR criterion are valued at only 50% of their cost in the credit calculation.

Biobased materials. SAN certification by the Rainforest Alliance certification could bring more rigor to an area in which, until now, any agricultural product has passed as “green.” SAN is gradually expanding its list of suppliers in order to meet LEED project teams’ needs. The Rainforest Alliance includes a handful of building product manufacturers in its list of certified companies, but you’ll have to contact the companies to determine which of their products are actually covered by that SAN certification.

In the meantime, the LEED Reference Guide acknowledges that the standard doesn’t yet have enough traction, and allows project teams to include products with “manufacturer-declared conformance” to SAN—see above. At present, LEEDuser isn't aware of any list of manufacturers meeting this requirement, but we'll stay tuned.

Wood products. Certification to Forest Stewardship Council (FSC) remains the standard in LEED for earning the certified wood credit. Certified products are widespread and usually available without a cost premium. To get credit for wood products certified under other systems, check out the Legal Wood pilot credit, described above.

The main sticking point to watch for with certified forest products is chain-of-custody documentation. For mass-produced products, LEED requires that you provide an invoice of the sale to the project that includes the supplier’s chain-of-custody certification number. For custom products, the invoice can be to the shop that produced the end product.

Certified wood products are commonly available—ask your supplier.

Materials reuse. Salvaged, refurbished, or reused products can contribute to credit compliance, as in previous versions of LEED. Finding these is usually a local effort, or you can work with a national supplier of salvaged materials, such as Planet Reuse.

Recycled content. As in previous versions of LEED, the recycled content value for LEED purposes is the sum of post-consumer recycled content plus one-half the pre-consumer recycled content, based on cost. There is no minimum threshold of recycled content that a product has to have to qualify, but each product contributes to the 25% threshold in proportion to its recycled content value.

Products with recycled content can be found in almost every product category, and most manufacturers are now well-equipped to provide the documentation that’s needed for LEED purposes.