OPTION 1: RAW MATERIAL SOURCE AND EXTRACTION REPORTING

This option focuses on corporate sustainability reporting—a well established, voluntary system common among large corporations. The credit lists several frameworks to choose from, but the Global Reporting Initiative (GRI) offers the most common one. Projects have to use at least 20 different permanently installed products from at least five different manufacturers to achieve this option.

There is no cost premium for products from those companies related to CSR. For projects pursuing this credit option, particularly for early adopters of LEED v4 who have not benefited from wider dissemination of LEED-compliant sustainability reports from major companies, there may be cost implications associated with reduced product selection. See MRc2 for more discussion of this issue.

OPTION 2: LEADERSHIP EXTRACTION PRACTICES

This credit option requires using products that meet at least one of the responsible extraction criteria below for at least 25%, by cost, of the total value of permanently installed building products in the project.

Extended producer responsibility (EPR)

This credit has no added cost.

Manufacturers offering EPR (or “takeback”) programs for their products usually do so for regulatory reasons, or in the case of carpeting, a combination of regulatory pressures and manufacturing processes that have gotten good at incorporating recycled content. The cost of EPR programs is typically incorporated into the entire product sector and therefore not a specific cost premium.

Bio-based materials

LEED v4 has increased the rigor for what it used to call “rapidly renewable materials” by requiring certification to the Sustainable Agriculture Network’s Sustainable Agriculture Standard (SAN). However, SAN isn’t ready for LEED v4 because the organizations involved with it have had their hands full targeting food-focused farms in developing countries.

Recognizing this, the LEED Reference Guide acknowledges that the standard isn’t ready and allows project teams to include products with “manufacturer-declared conformance” to SAN. Bamboo and other non-wood forest products that could be FSC-certified can also contribute here. At the time of this study, neither SAN certification nor its equivalent have seen the adoption needed to provide any cost information, although it is likely that we will see premiums for these products when they become available.

Wood products

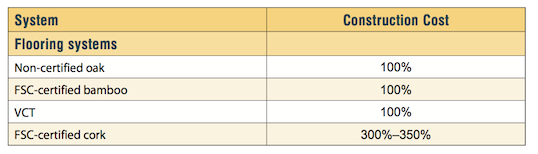

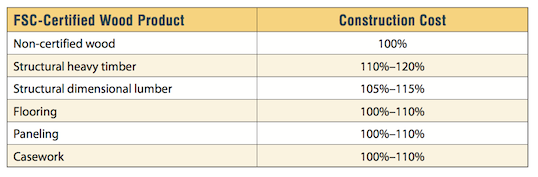

Cost premiums for wood certified to Forest Stewardship Council (FSC) standards varies considerably by market and application; the following are general estimates. Planning can be a factor; certified wood may not cost more, but check availability of specific quantities and pieces as early as possible so that it is available when needed.

Materials reuse

The cost of this credit is project-specific.

The cost of reused materials is very specific to the type of material being reused, its source, and other aspects such as architectural qualities. Reused materials may be free to a project (if reused from onsite), they may involve no cost premium (such as commodity lumber products), or they may come at a significant premium (for architectural products). Using free or low-cost materials often requires extra labor to prepare the materials for use. Use of these products is typically driven by project goals.

Recycled content

This credit has no added cost.

Thanks in part to LEED, recycled content has become a common feature of building products and is only associated with a cost premium if the product itself is a premium product—not because of the recycled content within it.

Cost Synergies

For products pursuing this and other credits involving detailed product information, there are cost synergies with that documentation effort.

MRc2: Building Product Disclosure & Optimization—Environmental Product Declarations

MRc4: Building Product Disclosure & Optimization—Material Ingredients

EQc2: Low-Emitting Materials