This credit had a major revision from v4 and now includes more paths and options to meet the intent, which is to reduce a project’s process water use. Option 1, which used to be the only path in v4, focuses on achieving an appropriate number of condenser water cycles in a cooling tower based on the concentration of various water quality parameters. In v4.1, two additional options are now included that enable design teams to pursue points by reducing the need for water-based heat rejection or by using recycled water for other end uses like humidification and boilers.

Option 1: Cooling Tower and Evaporative Condenser Cycles of Concentration

What do cooling tower cycles have to do with saving water?

A key parameter used to evaluate cooling tower operation is cycles. This is also referred to as ‘cycles of concentration’ or ‘concentration ratio’.

For a well-managed condenser water system, a cycle represents the extent to which water is used efficiently before being discharged via blowdown (where water is drained from cooling equipment in order to remove mineral build-up). A cycle is calculated as the ratio of the concentration of dissolved solids in the blowdown water compared to the make-up water.

From a water-efficiency standpoint, cooling tower cycles should be maximized to limit wasteful blowdown. However, any increase in cooling tower cycles should also be balanced with the build-up of dissolved solids, which can cause scale and corrosion problems unless carefully controlled.

Calculating the maximum cycles

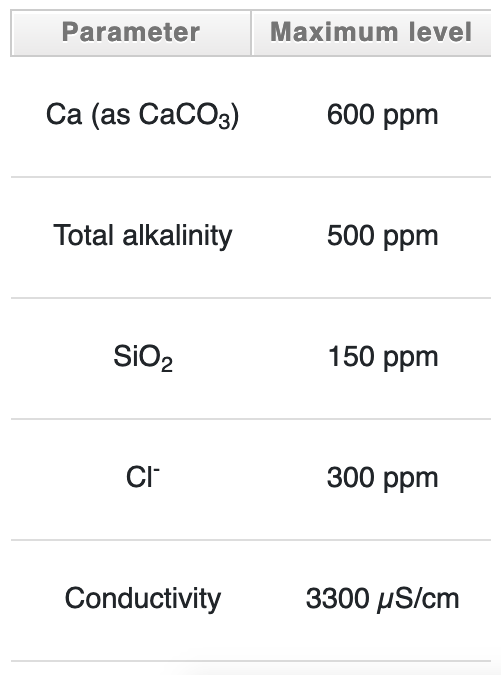

Option 1 requires a one-time potable water analysis to measure each dissolved solid (referred to in the credit language as control parameters) in the building’s supply water. Armed with this information, teams can then calibrate a cooling tower to achieve the maximum number of cycles without exceeding the maximum concentration of any of the control parameters. But be careful: the maximum concentrations for control parameters have been updated in v4.1, so be sure to reference the correct table.

The maximum number of cycles will vary depending on system type and the concentration of solids in the make-up water serving the cooling tower; however, it is common for cooling towers to operate in the range of 5–7 cycles.

Cooling tower vendors are usually able to assess the control parameters and implement a plan to meet the maximum cycles of concentration. They can also help determine if additional chemical treatments can be introduced in order to reach a higher number of cycles. For Option 1, the v4.1 credit awards projects an additional point for increasing the calculated number of cycles by 25%, with a third point available to Core & Shell projects that increase the calculated number of cycles by 30%.

If the project doesn’t have a vendor on board, another water treatment professional can be engaged to perform the potable water analysis. Alternatively, the cooling tower or evaporative condenser manufacturer may offer a water test kit.

What does each of the control parameters mean?

Here’s how each of the parameters can affect the performance of your cooling tower.

Ca (as CaCO3): Calcium (as Calcium carbonate)

Cooling towers chill buildings by evaporating water. A 100-ton chiller evaporates about three gallons of water per minute (11 L/min), with additional water loss from drift and blowdown. In a typical office building, HVAC equipment accounts for about a third of total water use.

Calcium carbonate is a very common form of scale found in cooling towers. Scale reduces a cooling tower’s heat exchange efficiency by insulating the equipment. Because of this, a major goal of most cooling tower chemical treatment programs is to prevent scale build-up.

Total alkalinity

Alkalinity is an indicator of acid neutralizing or acid buffering minerals in the water. High concentrations can lead to scale build up.

SiO2: Silica

Silica is one of the impurities that frequently play a big role in limiting the maximum cycles of concentration for a cooling tower. As concentrations increase past maximum levels, silica is likely to form scale deposits and insoluble sludge in the cooling tower.

Cl: Chloride

Chloride can be corrosive to most metals, which decreases the performance or longevity of the cooling tower.

Conductivity

Conductivity is a measurement of the water’s ability to conduct electricity. It’s also an indicator of the total dissolved mineral content of the water, since higher conductivity levels correlate to more dissolved salts in the water. By this logic, water with very few minerals present (think purified water) has very low conductivity.

High conductivity levels indicate increased risk of scale build up and lower performance for the cooling tower.

Other Considerations: Preventing Legionnaires’ Disease

Legionnaires’ Disease is a serious type of pneumonia caused by the Legionella bacterium. The bacteria have the ability to develop in both potable and non-potable water systems, but particularly in process water systems such as cooling towers.

Once Legionella develops in cooling tower water, it can be transmitted to people as small droplets of water that are released into the air. The bacterium is spread by water vapor only, and it cannot be transmitted by infected individuals to others. If contracted by a person, the health effects of Legionella can be lethal if left untreated.

Outbreaks of Legionnaires’ Disease occurred in New York and California as recently as 2015, serving as a reminder that proper management of biological growth should be an ongoing priority for building designers and operators.

How cooling tower materials affect cycles of concentration

Owners and design teams should know that the material used to construct a cooling tower can determine the maximum concentration levels a given manufacturer allows without voiding the warranty. Stainless steel typically costs more than galvanized steel but allows for higher concentration levels of certain parameters.

Reviewing the options from this perspective is prudent when considering a new tower. Manufacturers can provide recommended concentration levels for galvanized and stainless steel. Keep in mind that recommended concentrations can be specific to the manufacturer and piece of equipment that is installed at the building.

Option 2: Optimize Water Use for Cooling

The intent of this option is to reduce the water consumption in a building’s chilled water loop; it allows projects to claim points by demonstrating a reduction compared to a baseline. To be eligible for this option, projects should have a water-cooled chiller in the baseline that can be used as a reference to calculate the water reduction. An important note is that this credit option uses ASHRAE 90.1–2016 as the reference standard for the baseline.

By utilizing variable-speed fans in the cooling towers and limiting drift to 0.002% of recirculated water volume, projects can reduce the water use in the chilled water loop and achieve one to two points for a 25% or 50% reduction, respectively.

Core & Shell projects also have the option to achieve three points for a 100% reduction, which effectively means eliminating the need for a cooling tower. This is possible in scenarios where Appendix G requires a baseline system with a chilled water loop and the proposed design uses another type of heat rejection, like a ground-source system or air-source VRF.

Option 3: Reduce Process Water Use

Process water, such as that used in a humidification system or for heating hot water boiler, also represents a significant portion of a building’s potable water use. Option 3 awards projects one to two points for using a recycled alternative source of water to meet at least 20% or 30% of process water demand, respectively. To be eligible, the process water use must represent at least 10% of total building regulated water use, and water used for cooling cannot be included, as this is addressed in other options.

Projects pursuing this option may need to explore a water purification system to ensure any recycled alternative water is suitable for the target process use; this is particularly relevant for humidification systems. Refer to the Rainwater Management credit for guidance on evaluating the quantity of rainwater available at the project site for reuse, and ensure the energy impacts of any additional systems are considered.

What’s New in v4.1

- For Option 1, the maximum concentrations for cooling tower water control parameters have changed .

- The Option 1 threshold for 2 or more points has been changed from a minimum number of cycles to a percentage increase above the calculated number of cycles using additional water treatment.

- Option 1 now includes a three-point pathway for Core & Shell projects.

- Option 2 is new and offers up to two points (three points for Core & Shell) by demonstrating a percentage reduction in cooling water use compared to a baseline.

- Option 3 is new and offers up to two points (three points for Core & Shell) for using recycled alternative water to meet other building process water demands besides water used for cooling.

Should I Upgrade?

Generally speaking, most projects will find upgrading offers greater opportunity and more flexibility to demonstrate process water savings and achieve points.