CWM Planning Prerequisite Eliminated

Although LEED v4.1 included this prerequisite when it was released, addenda issued on November 9, 2020 deleted this prerequisite. Projects are held to the rating system requirements at the time of registration. This means that any project registered prior to this change will need to submit a construction waste management plan. Note that although the prerequisite was eliminated, project teams still have to create a CWM plan and reporting process (see below for more details).

Although the corresponding prerequisite for this credit was eliminated with the November 9, 2020 addenda, this credit still requires that a waste management plan and report be submitted. The plan is required to identify diversion strategies, establish waste diversion goals, and describe the implementation strategies.

The big change in the LEED 4.1 version of this credit is that waste diversion is only worth up to one point, whereas in v4 diversion could earn up to two points. The one point in v4.1 is achieved at the 50% waste diversion threshold, a relatively easy threshold to meet, especially since the requirement for 3 different material streams has been eliminated.

Option 2 of the credit targeting total waste reduction increases the waste generation limit from 2.5 pounds per square foot in v4 to 15 pounds per square foot for one point and 10 pounds per square foot for two points. Recycling can mean the material becomes a new product like wood derived fuel, road base, soil conditioner, or other commodity items. Remember ADC, soil, and land clearing debris are still considered waste. We have found that projects that include demolition of a medium existing building can achieve one point under this option, and with a little planning can achieve two points.

Two Ways to Manage Waste on Your Project

This credit rewards projects that implement the construction and demolition waste management (CWM) plan. Project teams have two options for credit achievement—either diverting waste from the landfill or reducing overall waste generated. Details on each option are outlined below.

Option 1: Diversion percentages with a new twist

As with LEED 2009 and v4, Option 1 focuses on diverting construction and demolition waste from landfills by finding alternatives, including recycling or salvaging (via reuse onsite, donation for reuse on another site, or resale). This should feel pretty familiar.

The credit requires 50% diversion of the total construction and demolition debris. Yes, demolition of existing buildings, portions of buildings, etc. are included in credit calculations. This means that documentation of the credit starts as soon as demolition does, and these waste streams must be measured.

Option 2: Reduction of total waste requires integrative design thinking

As an alternative to diversion, Option 2 requires teams to think about and plan for not generating waste in the first place, which is a new way of dealing with construction waste reduction for LEED. Option 2 directs teams to reduce total waste material and not generate more than 15 pounds per square foot of the building’s floor area (75 kilograms per square meter) for one point or 10 pounds per square foot of the building’s floor area (50 kilograms per square meter) for two points.

Implementing this option requires that building be designed to generate less waste from the very beginning. Design strategies such as prefabrication, modular construction, or using standard material lengths or sizes in the project’s design can all help reduce waste for this path to earn the credit. To get the most benefit, this option requires teams to plan for source reduction during design and implement it during construction.

Before using Option 2, teams should estimate the amount of waste for the project to determine whether the performance threshold is realistic. Additionally, teams must address the use of source reduction in their construction waste management (CWM) plan.

Who is responsible for Documentation?

The general contractor should provide a waste report detailing all major waste streams generated and include disposal and diversion rates.

Key Terms and Concepts to Know

Onsite separation vs. commingled collection

Teams must include collection and sorting methods as part of their CWM plans. Depending on what is appropriate, projects are likely to use a combination of onsite separation and commingled collection. In addition, teams may consider other waste-stream-diversion tactics like deconstructed materials sent to reuse markets, reuse of deconstructed materials, and takeback programs from manufacturers.

For onsite separated (a.k.a. source separated) materials, each type of material sent to a separate recycling facility counts as a single stream. If, however, a single material is being diverted to several streams, each stream is counted separately. An example of two waste streams for a single material would be wood waste that going to a power generation facility as fuel and to local building supply to be reused.

To count toward the credit, commingled recycling facilities must be able to provide project-specific diversion rates or an average diversion rate for the facility that is regulated by the local or state authority. Visual inspection is not an acceptable method of evaluating diversion rates.

If the commingled recycling facility can track and produce documentation of specific materials recycled for your project, you can count commingled waste as multiple waste streams.

Otherwise, commingled waste that is average diversion rate for a regulated facility sent to the same recycling sorting facility is counted as a single waste stream regardless of how many different materials are included. The average recycling rate for the facility must exclude alternative daily cover (ADC). The facility’s average diversion rate must be reviewed or documented by a state, county, or other local authority for the commingled waste to contribute toward the diverted waste total. GBCI hasn’t offered a lot of definition around how “regulated” the facility is to be, so assume any kind of oversight, review, or certification is acceptable.

Source reduction is a viable option

The credit addresses a new way of achieving CWM—via source reduction. Source reduction eliminates project waste through prefabrication, modular construction, or incorporating standard material lengths or sizes into the project’s design to eliminate waste.

To get the most benefit, this option requires teams to plan for source reduction during design and implement it during construction. Teams planning to utilize source reduction as the credit achievement option should address its use in their CWM plan.

Alternative Daily Cover (ADC) still does not count

There was a big change in CWM between LEED 2009 and LEED v4. Alternative daily cover (ADC) no longer qualifies as diversion. Any materials that are used for ADC must be counted as landfilled, and your CWM plan must account for this.

Land-clearing debris and hazardous materials are still out but must be accounted for

As with LEED 2009 and v4, land-clearing debris materials that are natural (like rock, soil, stone, and vegetation) are not considered construction, demolition, or renovation waste. Consequently, teams should not include these materials in their calculations, although their CWM plans must account for these materials.

Similarly, teams must document the safe removal and disposal of hazardous materials in their CWM plans but exclude these materials in their calculations.

Incineration can be considered diversion in certain cases

As in v4, incineration can be diversion, but only if reuse and recycling methods are not readily available in the project’s location and a team can demonstrate they exhausted these strategies before sending waste material to energy facilities.

In those cases, waste-to-energy incineration may be considered diversion, and it must be included in the CWM plan. Teams must follow European Commission Waste Framework and Incineration Directives, and the waste-to-energy facility must meet the applicable European standards based on fuel type.

Note: The combustion of waste wood (“wood-derived fuel” or biofuel) is considered diversion and not subject to the additional requirements for waste-to-energy incineration. The definition of a wood-derived fuel is basically waste that is made into a product that can be sold for another use like fuel.

Waste report can be by weight or volume

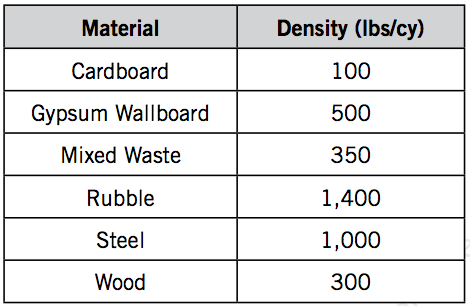

Teams can calculate the diversion rate by weight or volume, as long as they are consistent. The diversion rate is calculated by dividing the total waste diverted from the landfill by the total waste generated by the project and multiplying the result by 100.

As the LEED v4 Reference Guides for BD+C and ID+C do not include solid waste conversion factors tables, teams may want to utilize Table 2: Volume-to-Weight Conversion for Construction and Demolition Debris for the Construction Waste Management credit in the LEED BD+C: Multifamily Midrise in the Credit Library as a resource. These resources still apply in v4.1 unless new tables are published.

Other Waste Diversion Strategies

As mentioned, teams may consider other waste-stream diversion tactics like sending deconstructed materials to reuse markets, reuse of deconstructed materials, and takeback programs from manufacturers.

Deconstructed materials can also be donated to charity or sent to another project site. As with commingled waste, donation also counts as a single waste stream unless the receiving organization can verify and track the individual materials that are donated. This is another example of a multiple material types constituting a single waste stream when additional documentation is not available.

For deconstructed materials that are reused onsite, no distinction is made between whether the materials are serving their original function or not. In this case, each material reused onsite for each purpose counts as a single waste stream.

Takeback programs are offered by product manufacturers who will accept shipments of materials removed during renovation and/or purchased overruns of their products. This type of waste stream is defined by the specific material type. For example, you would have two distinct waste streams if you had carpet sent to a takeback program from a carpet manufacturer, and ceiling tile sent to a takeback program from a ceiling tile manufacturer.