This credit invites project teams to look under the hood at how their products are sourced—what raw materials are harvested? Is the product made in such a way that reduces resource depletion and protects ecosystems? Teams can earn one to two points for selecting a minimum percentage of products by cost with Forest Stewardship Council (FSC) certification, materials reuse, recycled content and/or several other categories of sustainable attributes.

You can mix and match products that meet any of the attribute criteria to get to 15% of materials (by cost). For products with a mix of attributes, like a carpet tile with 25% recycled content and a take-back program, you can double-count the product for meeting each of these two criteria. Be careful, though; for FSC-certified recycled content wood, you must choose one criterion or the other (no double-counting!).

As of Q2 2021, the sustainable material thresholds have been lowered from 20% and 40% to 15% and 30%, making achievement even easier for projects with smaller budgets or limited structure and enclosure scope. Note that for the 15% threshold (1 point), you must have products from at least three different manufacturers. That goes up to five for the 30% threshold (2 points). You can even earn an exemplary performance innovation point for spending 45% of your total materials budget on products with at least one of the eligible sustainable attributes.

Many of the attributes referenced in this credit will be familiar to veteran LEED users, but some are still getting off the ground.

ASTM D6866

ASTM D6866 (or ISO 16620-2 internationally) defines how products should tested for biobased content; after testing, products are assigned a percentage. Non-wood products must be tested according to this standard. Multiply the percent biobased content by 50% to determine your percentage by cost.

Why not by 100%? Because in order to count fully, products must be certified to the Sustainable Agriculture Network (SAN) standard, which was introduced to certify biobased materials that may not fall under the wood or bamboo category—such as cotton, wool, straw, soy, or corn-based polymers. As a program of the Rainforest Alliance, the SAN standard ensures that crops are responsibly sourced according to ten categories, including everything from wildlife protection to occupational health.

SAN certification by the Rainforest Alliance could bring more rigor to an area in which anything with an agricultural basis has passed as “green.” However, very few products are actually certified under this program, and no other programs have been approved as equivalent.

Extended Producer Responsibility (EPR)

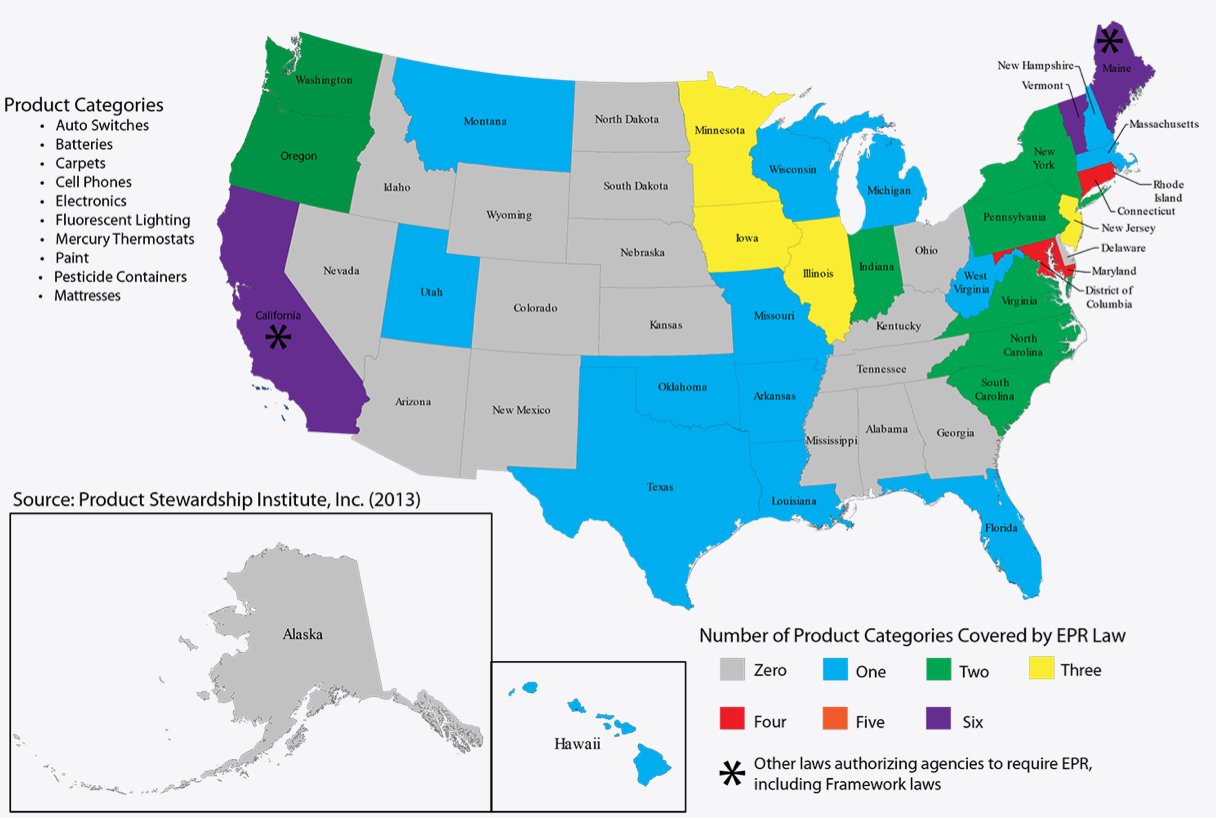

Better known as “product take-back,” EPR means that a manufacturer has set up systems to reclaim its products at the end of their useful life and to recycle them into the same product in a “closed loop,” or to otherwise dispose of them safely and in the most productive way.

It has become common to see building products advertised as “recyclable,” but some manufacturers have stretched that term to the limit, using it as a label for new product lines for which established, closed-loop recycling processes haven’t made it out of research and development. LEED v4 requires compliant EPR products to have established programs that include program literature and contact information.

It has become common to see building products advertised as “recyclable,” but some manufacturers have stretched that term to the limit, using it as a label for new product lines for which established, closed-loop recycling processes haven’t made it out of research and development. LEED v4 requires compliant EPR products to have established programs that include program literature and contact information.

LEED allows for EPR programs that are run by other organizations, so it’s not necessary that each manufacturer have its own take-back program. But any independent initiative must have documentation that the materials it is “taking back” are actually being recycled at a high rate.

The Legal Wood Pilot Credit

Depending on whom you ask, this 2016 pilot credit is either an attempt to test out a potential future prerequisite that would prevent LEED projects from using illegally harvested wood, or a back-door into LEED for timber that is certified under programs that the wood products industry prefers instead of FSC.

In effect, it’s both.

Unlike many pilot credits, that are basically pre-approved innovation points, this one is an “alternative compliance path” (ACP). That means that rather than using up one of a LEED project’s limited Innovation points, it’s an alternate route to earning this credit.

Instead of only allowing wood that is FSC certified to count, this ACP endorses any forest certification program that meets the requirements of ASTM D7612-10, “Standard Practice for Categorizing Wood and Wood-Based Products According to Their Fiber Sources,” as long as the project’s wood products also meet two other requirements:

- All wood has to pass a basic screen for risk of illegal harvesting, and provide additional documentation if it isn’t low risk; and

- At least 70% (by cost) of the wood has to meet the ASTM’s standard for “wood from responsible sources.”

Other certification programs (in addition to FSC) specifically cited in the appendix to the standard are:

- Sustainable Forestry Initiative (SFI)

- American Tree Farm System (ATFS)

- Programme for the Endorsement of Forest Certification schemes (PEFC)

- Canadian Standards Association Sustainable Forest Management Standard Z-809 (CSA-SFM)

Finding LEED-compliant products

The products you need can be found in different places for each attribute—although you can try out the Better Materials search program first to see if any products meet your criteria. Your best bet with evaluating sustainable attributes is to contact your supplier and request letters of verification.

Extended producer responsibility (EPR): EPR is fairly common in carpeting, and some companies in other industries are advertising LEED compliance. However, most EPR programs are in response to state regulations for products with concentrated toxic content like mobile phones and fluorescent lamps, and aren't likely to contribute very much to the cost basis required for earning this credit. Paint is an exception; in some places used paint collection programs can qualify. Note, however, that products meeting the EPR criterion are valued at only 50% of their cost in the credit calculation.

Biobased materials. Products with verified biobased content provide an alternative to petroleum-derived or non-renewable materials. To document verified content, ask your supplier for confirmation that the ASTM D6866 test method was conducted, including the percent by weight of biobased material within the product. Alternatively, if the product has been certified to the USDA BioPreferred Program, provide the Voluntary Labeling verification of bio-based content via ASTM 6866 or ISO 16620-2 testing.

SAN certification by the Rainforest Alliance certification could bring more rigor to an area in which, until now, any agricultural product has passed as “green.” SAN is gradually expanding its list of suppliers in order to meet LEED project teams’ needs. The Rainforest Alliance includes a handful of building product manufacturers in its list of certified companies, but you’ll have to contact the companies to determine which of their products are actually covered by that SAN certification.

Wood products. Certification to Forest Stewardship Council (FSC) remains the standard in LEED for earning the certified wood credit. Certified products are widespread and usually available without a cost premium. To get credit for wood products certified under other systems, check out the Legal Wood pilot credit, described above.

The main sticking point to watch for with certified forest products is chain-of-custody documentation. For mass-produced products, LEED requires that you provide an invoice of the sale to the project that includes the supplier’s chain-of-custody certification number. For custom products, the invoice can be to the shop that produced the end product.

Certified wood products are commonly available. Ask your supplier.

Materials reuse. Salvaged, refurbished, or reused products can contribute to credit compliance, as in previous versions of LEED. Finding these is usually a local effort, or you can work with a national supplier of salvaged materials, such as Planet Reuse.

Recycled content. As in previous versions of LEED, the recycled content value for LEED purposes is the sum of post-consumer recycled content plus one-half the pre-consumer recycled content, based on cost. There is no minimum threshold of recycled content that a product has to have to qualify, but each product contributes to the 15% threshold in proportion to its recycled content value. Most project teams are likely to find that a very large portion of compliance comes from recycled content in structural steel, rebar, metal joists and deck, and other metals.

Products with recycled content can be found in almost every product category, and most manufacturers are now well-equipped to provide the documentation that’s needed for LEED purposes.

What’s New in the LEED v4.1 beta

- The previously unachievable Option 1 has been removed.

- With the removal of Option 1, the actions that were part of Option 2 can earn up to two points in v4.1, with a 20% by cost threshold for one point, and double that for two.

- Reused materials now count for 200% of their cost.

- There is no longer a 30% cap on the number of contributing products coming from the structure and enclosure.

Should I upgrade?

With that second point theoretically achievable, and with no limit on structure and enclosure products, an upgrade is definitely worth looking into. You could also benefit if you plan to reuse materials.