This credit has one point for transparency and a second point for reducing impacts.

The intent behind this approach is that there is not enough good data available in the market on the environmental footprint of products, and that before we can expect the industry to improve, we have to get better at measuring the things we care about. That’s why the first point rewards teams for using products that come with data about their environmental impacts (such as environmental product declarations, or EPDs), even if those impacts are bad. The second point rewards teams for using products with lower impacts.

Option 1: Just Use 20 Products with EPDs (or 10 for some projects)

Option 1 outlines several ways that products can contribute to achieving this point. Some of the pathways offered in v4 used to be valued at less than a full product, but they’ve gone up to whole points now. Products with third-party-verified (Type III) EPDs newly count as a product-and-a-half.

There are enough product-specific EPDs available that most projects should have little trouble finding the 20 products that are required to earn the point. Only ten products are needed for core and shell projects, tenant improvement projects, and warehouses and distribution centers. We recommend starting with acoustic ceiling tiles, paints/coatings, flooring, and insulation. With so many products with disclosures on the market, you may easily climb to double the requirement—40 products (20 for rating systems that require ten) and claim an exemplary performance innovation point.

There are enough product-specific EPDs available that most projects should have little trouble finding the 20 products that are required to earn the point. Only ten products are needed for core and shell projects, tenant improvement projects, and warehouses and distribution centers. We recommend starting with acoustic ceiling tiles, paints/coatings, flooring, and insulation. With so many products with disclosures on the market, you may easily climb to double the requirement—40 products (20 for rating systems that require ten) and claim an exemplary performance innovation point.

If you want to include some industry-wide EPDs in your count, be sure that they clearly identify the manufacturer of the product you’re using as a participant in the program. Industry-wide EPDs that don’t list your manufacturer as a participating company are not eligible.

What Counts as a Separate “Product”?

As soon as USGBC introduced the idea of earning a point based on how many products meet the criteria, questions arose about what counts as a separate product. If you use two different colors of the same paint, is that one product or two?

Since then, USGBC has issued guidance that makes things pretty clear (at least in most situations—it’s hard to anticipate every situation that might emerge!). If two versions of a product differ only in appearance, they only count as one product, not two. Two colors of the same flat paint are just one product. But if the two versions differ in function, then you are free to count them as two separate products. So if your two paints have different gloss levels, like a flat navy wall paint and a semigloss white for trim, then you can count them as two products.

Similarly, if you’re buying a set of windows that are all the same except for their dimensions, they would only count as one product. But if some of them are operable and others fixed, then you can count each type as a separate product—up to the cap of five per manufacturer.

When it comes to assemblies, or things made up of components, the basic question to ask is, “How is this assembly delivered to the job site?” A window is made up from a lot of different components: insulated glazing unit, spacers, frame, nailing fins—but it’s just one product, unless you’re assembling that window onsite by building your own frames. In the case of onsite assembly, the glazing unit and the materials used to make the frames would each count as separate products.

What’s an Environmental Product Declaration (EPD)?

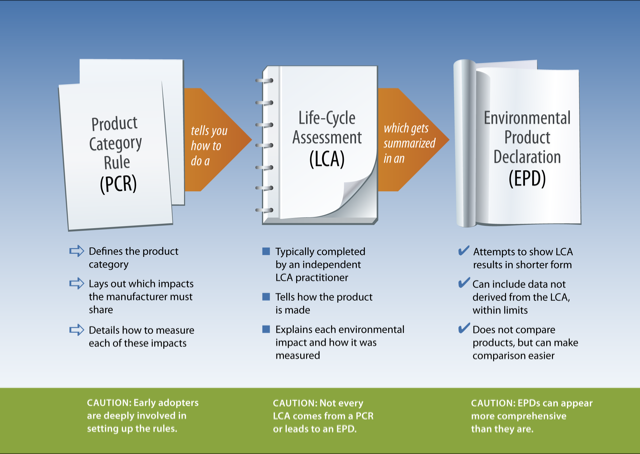

EPDs, formally called “Type III Environmental Product Declarations” by ISO, are independently verified reports based on life-cycle assessment (LCA) studies. The LCA studies must have been conducted according to a set of common rules (“product category rules,” or PCRs) for each product category and then peer reviewed.

At the heart of the EPD process are “program operators”—organizations that ensure that the EPDs meet the various requirements.

At the heart of the EPD process are “program operators”—organizations that ensure that the EPDs meet the various requirements.

UL Environment is the leading program operator in the U.S., responsible for the great majority of EPDs that have been published to date. These include generic, industry-wide EPDs for the American and Canadian Wood Councils as well as product-specific EPDs for several carpet companies and other major manufacturers. Other organizations serving as program operators include NSF International and ICC Environmental Services (ICC-ES), a subsidiary of the International Code Council.

These program operators don’t do the actual LCA studies behind the EPDs. They simply ensure that the studies follow the appropriate product category rules and that they’ve been translated properly into the EPD format. Because EPDs are relatively new in the U.S., the program operators have been busy sorting out the product category rules while trying to meet ISO’s stipulation to avoid creating duplicate PCRs within a product category. When program operators attempt to produce the first U.S.-based EPDs in a category, they can either create a PCR from scratch—as ICC-ES has done for pressure-treated wood—or adapt one from Europe, which has been UL Environment’s preferred approach.

Make Sure Your EPDs Qualify

EPDs from well established program operators generally meet LEED’s requirements, but it’s good to know what those requirements are and confirm that each declaration is compliant. Unless you’ve studied the relevant ISO standards and EN 15804 (which governs the product category rules process), you might find the details a bit overwhelming, so here are the basics:

- You can provide either a full EPD or a summary report with a link to the full EPD. Whichever you upload, it has to list the manufacturer name and EPD program operator, and a product description.

- Environmental life-cycle assessment—the science behind the EPD—relies on a method for quantifying environmental impacts. The EPD has to say which standard impact assessment was used—typically either TRACI or CML.

- Life-cycle assessments vary in how much of the product’s life cycle they cover. For LEED, the scope has to be at least “cradle-to-gate,” meaning that it has to include the extraction of raw materials and cover all the steps up to the product’s final manufacture. “Gate” in this case refers to the gate of the factory, meaning the product is ready to be distributed.

- There is a set of official information that’s included on every qualifying EPD, including:

- Who the program operator is

- When the EPD was published, and how long it’s valid

- Which product category rule (PCR) it follows

- Who reviewed the PCR

- Who independently verified that the EPD meets ISO 14025

- Who verified that the life-cycle assessment behind the EPD conforms to ISO 14044 and the stated PCR

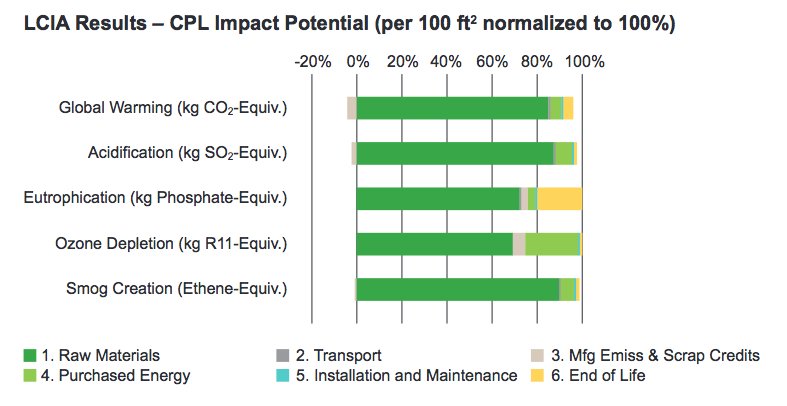

- LCA results for the product have to cover at least the six basic environmental impact categories:

- global warming potential (greenhouse gases), in CO2e;

- depletion of the stratospheric ozone layer, in kg CFC-11;

- acidification of land and water sources, in moles H+ or kg SO2;

- eutrophication, in kg nitrogen or kg phosphate;

- formation of tropospheric ozone, in kg NOx, kg O3 eq, or kg ethene; and

- depletion of nonrenewable energy resources, in MJ.

It makes things easier for the reviewers (and therefore they might be more inclined to give you the benefit of the doubt) if you take the trouble to highlight the required information on whatever files you submit.

This might seem obvious, but quality control is a problem with a surprising number of LEED submissions. Be sure to check that the EPD or summary you provide matches the product listed in the form (and in the materials calculator), and if you link to full EPD make sure the link goes to the same product.

Note that through the new program known as “Better Materials,” it’s much easier to find and document products because they may be pre-verified by GBCI. But few products are available in the system so far.

Option 2: Beating the Benchmark

Option 2 has gotten way easier since LEED v4, especially given LEED v4.1 addenda updates: to comply, you must specify only five permanently installed products showing either a plan to improve life-cycle impacts (one-half product) or actual improvements in life-cycle impacts (one to two products).

You have a number of pathways for earning the one point available under Option 2. Put simply, products with a plan for reducing life-cycle impacts are counted as one-half a product, and products showing reductions in embodied carbon (the upfront greenhouse gas emissions from producing a material) count as one product or more. To demonstrate reductions in embodied carbon, the product LCA or EPD must compare the product to a baseline and report relative savings across impact categories, including global warming potential at minimum.

You’ve got a number of pathways for this option, but to simplify, it comes down to this: products with a plan for reducing life-cycle impacts count for half, and products showing reductions in embodied carbon (the upfront greenhouse gas emissions from producing a material) count as one product or more.

As with the other BPDO credits, you can get extra credit for using local materials, but only if they’re both extracted and processed within 100 miles (160 km) of the project site.

Unlike in v4, there’s no limit on how many of the products can be structure and enclosure materials.

Where to find LEED-compliant products

Currently, the most extensive list of EPDs openly available in the U.S. is in UL’s SPOT database, which lists products with EPDs along with many other certified claims (such as VOC emission certificates, helping to streamline documentation for projects pursuing IEQc Low-Emitting Materials). The Sustainable Minds Transparency Catalog, ORIGIN and Ecomedes also offer extensive libraries.

To explore all these databases simultaneously, your best bet is to use the Better Materials system, which is a meta-database incorporating Spot and several other databases. You do one search through Better Materials, and it loads searches from other databases. Some of the products that come up may even be pre-verified, simplifying search and documentation.

What’s New in LEED v4.1

- Getting to 20 products was doable for a typical whole building but daunting for a tenant fit-out or warehouse that used only a small selection of products. Those simpler project types now need only ten products from three manufacturers.

- The previously unachievable Option 2 is completely revised to make it much easier. The thresholds that were out of reach have been cut drastically, from 50% and 25% down to only five products total (this is because so few products meet the requirements).

- There is no longer a 30% cap on the number of counted products coming from structure and enclosure..

- EPDs that show reduced embodied carbon are given extra credit.

Should I upgrade?

Upgrading on this one is a no-brainer since you can, in theory, show reduced environmental impacts, which was impossible under LEED v4.