Hi Michelle,

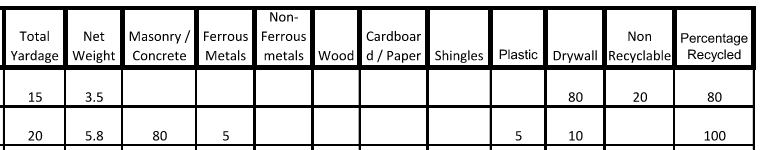

I thought I'd better post this under NC also. I've never used volume for any waste diversion calcs before, but my urban CI project is struggling to figure out how to comply with the new source separation requirements with no room on site for extra bins and no commingled facilities that will provide project specific diversion. If waste streams need to be 5% of the total waste to actually constitute a waste stream, how do you figure out if they will be? What do you do if at the end of the day they're not? Will the USGBC actually not consider wood or cardboard a waste stream, even with an on-site source separation strategy, if it doesn't equal 5% of the total waste diverted?

It seems to me that using volume measurement would broaden the potential waste streams. Materials that are lighter like cardboard may not constitute 5% by weight but might by volume. Since the reporting and receiving facility receipts are generally tonnage oriented, how do we substantiate volume? Am I correct in assuming that one would simply say a 2cuyd container was hauled to the facility so the volume is 2 cuyds? What if the container is not full? Could one divide a larger container into smaller spaces inside for separate waste streams and then claim the volume of that smaller space for each stream when the larger container is hauled away? It doesn't seem as if volume metrics would be as precise and easily verified as weight metrics, so do I have the right sense of how the documentation would work? I'm concerned that this doesn't seem much different than eyeball audits

If the facility can provide documentations, will each material in this comingled container now count as separate material source?Additionally if for example I have two dumpsters one is commingled and the other is only for one material such as cardboard, but they go to the same facility, can I count them as two separate material sources. How do I document this?Lastly how can I strategize this in the waste management plan? How can i describe this in there. I've been using charts, but I don't know if something is comingled if it can count as a separate material in the end. Please advise.

If the facility can provide documentations, will each material in this comingled container now count as separate material source?Additionally if for example I have two dumpsters one is commingled and the other is only for one material such as cardboard, but they go to the same facility, can I count them as two separate material sources. How do I document this?Lastly how can I strategize this in the waste management plan? How can i describe this in there. I've been using charts, but I don't know if something is comingled if it can count as a separate material in the end. Please advise.