Regional materials are those that are extracted, harvested, and manufactured within a certain distance of your project site.

How far, exactly? Historically LEED has used a 500-mile radius to define regional products, but that made it difficult or impossible for coastal or remote regions to pursue this credit. A July 2012 LEED addendum added a more flexible approach, and now MRc5 offers two options to LEED 2009 projects:

- Option 1: The old familiar option, uses a simple 500-mile radius from the site for both extraction and manufacturing distance.

- Option 2: This new option allows you to do a prorated calculation based on the lower relative impact of shipping materials by rail or water. Calculate a 500 mile (800 km) total travel distance to the project site using a weighted average. Distance by rail can be divided by 3; distance by inland waterway by 2, and distance by sea by 15.

The Option 2 credit calculation is much more complicated, and finding the necessary information could be a lot of work. It will be a most effective option for projects that really need to earn the credit, and can ideally focus their calculations on a handful "big ticket" items—see below.

Research early and often

Begin researching products early—this will help ensure that there are sufficient regional materials available to specify. If you delay your research, you run the risk that non-regional materials may be specified and purchased before you find a regional alternative. Use the estimated project budget to keep tabs on your performance against the credit threshold.

Many projects fail to earn this credit because they wait until all the materials are purchased before doing the credit calculations.

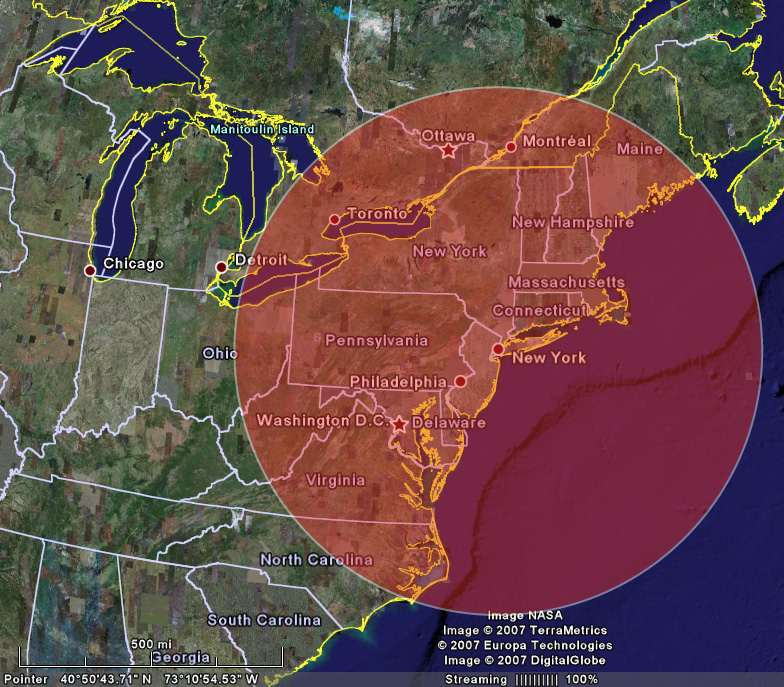

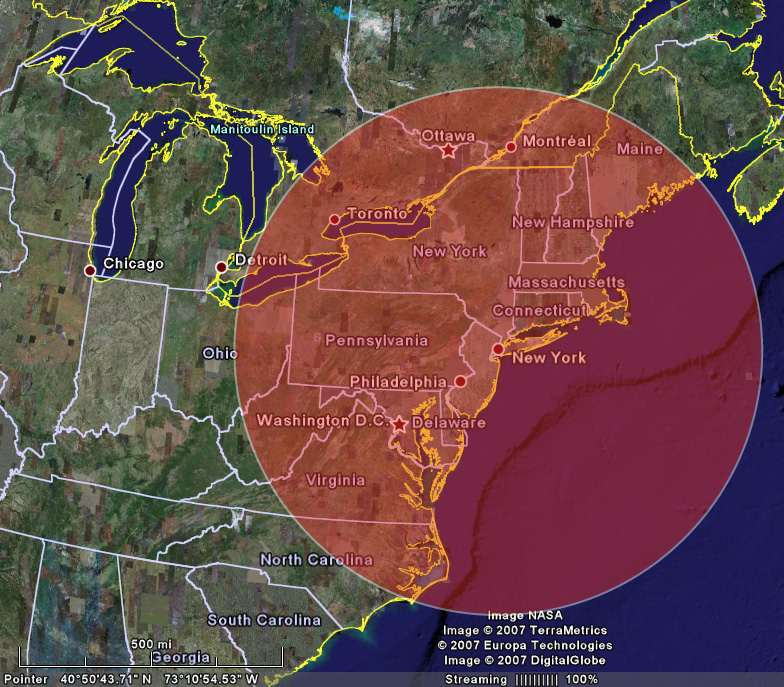

The 500-mile radius is big enough to cover a lot of ground, but depending on your location, can be tough to work with. Seeing the radius on a map can help quickly assess the product areas where you might have better luck.

“Big ticket” items are just the ticket

If there are enough materials available in your region, this credit can be very easy to achieve. Focusing on a few more expensive items that can be sourced regionally—like structural steel or concrete, for example—may represent enough value to earn the credit. If you combine these big-ticket items with the requirements of other MR credits, you can earn multiple points for a relatively small number of product selections. This strategy has the benefit of reducing the number of items you need to track and document.

Finding the origins of your materials

Often, product manufacturers will get their materials from a wide variety of sources, making extraction location trickier to determine. It can also be challenging to understand how LEED determines the manufacturing locations for materials that are salvaged onsite or reused, those that contain recycled content, or are part of assemblies. Use the chart below to clarify how you should document the manufacturing and extraction location for these materials.

You can claim recycled content as a regional material, and you don't have to trace it back to its original extraction location. According to the LEED Reference Guide, the extraction point for recycled materials is the location of the raw material prior to the manufacturing of the final building product. That might be the recycling facility, scrapyard, depository, stockpile, or another location where the material was collected and packaged for market purchase before manufacturing. It is not necessary to track the raw material back to its original point of extraction.

For a product with multiple points of manufacture, the point of manufacture should be listed as the location farthest from the site.