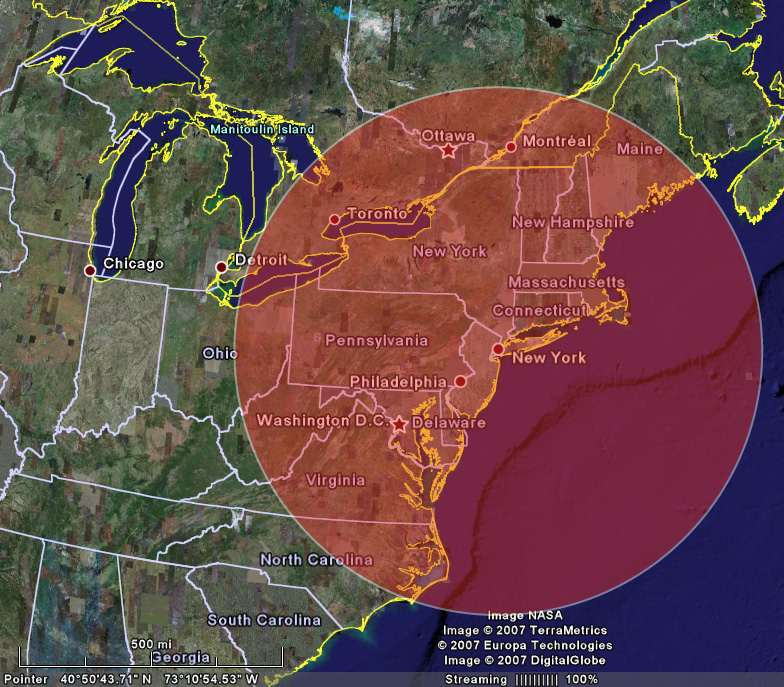

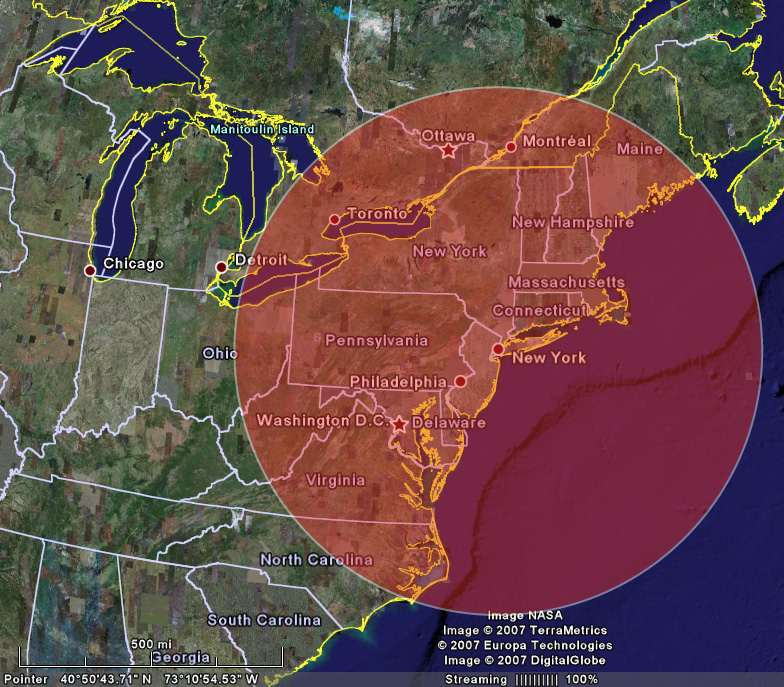

Regional materials are those that are extracted, harvested, or manufactured within 500 miles (as the crow flies) of your project site.

Regional materials are those that are extracted, harvested, or manufactured within 500 miles (as the crow flies) of your project site.

You may already be aware of the materials that are produced in your region, and in some areas this is easy—it’s no surprise, for example, that the town of Gypsum, Colorado, extracts the raw materials to make drywall, and projects within 500 miles of Gypsum would be wise to source their drywall from there.

Five hundred miles is a long way and you might be surprised how much is extracted and produced in your region. Some coastal or remote regions, or those with less of a manufacturing base, may not find it worthwhile to pursue this credit, however.

Research early and often

Begin researching products early—this will help ensure that there are sufficient regional materials available to specify. If you delay your research, you run the risk that non-regional materials may be specified and purchased before you find a regional alternative. Use the estimated project budget to keep tabs on your performance against the credit threshold.

Many projects fail to earn this credit because they wait until all the materials are purchased before doing the credit calculations.

“Big ticket” items are just the ticket

If there are enough materials available in your region, this credit can be very easy to achieve. Focusing on a few more expensive items that can be sourced regionally—like structural steel or concrete, for example—may represent enough value to earn the credit. This strategy has the benefit of reducing the number of items you need to track and document. If you combine these big-ticket items with the requirements of other MR credits, you can earn multiple points for a relatively small number of product selections.

Focus on furniture in CI

Furniture can often be more expensive than building materials, and it may be quite easy to find refurbished furniture within a 500-mile radius.

Other special considerations for CI

LEED-CI approaches this credit differently than the other LEED rating systems. There are two points available under this credit; the first is easier to achieve because it only requires that you collect manufacturing information, which is not usually difficult to get. The second credit is more challenging because you must research and obtain extraction locations as well, which are often quite difficult to find.

Finding the origins of your materials

Often, product manufacturers will get their materials from a wide variety of sources, making extraction location trickier to determine. It can also be challenging to understand how LEED determines the manufacturing locations for materials that are salvaged onsite or reused, those that contain recycled content, or are part of assemblies. Use the chart below to clarify how you should document the manufacturing and extraction location for these materials.

You can claim recycled content as a regional material, and you don't have to trace it back to its original extraction location. According to the LEED Reference Guide, the extraction point for recycled materials is the location of the raw material prior to the manufacturing of the final building product. That might be the recycling facility, scrapyard, depository, stockpile, or another location where the material was collected and packaged for market purchase before manufacturing. It is not necessary to track the raw material back to its original point of extraction.

For a product with multiple points of manufacture, the point of manufacture should be listed as the location farthest from the site.