Flush-Out

The cost of flushing is driven by the time needed to complete the flush to meet the credit requirements, and the energy for the heating or cooling of the outside air needed to maintain the interior space conditions. This will be driven by project size, type, time of year, and climate.

Occurring at the end of construction when time and money may be in short supply, this task must be budgeted and planned early and carefully. On the plus side, flushing commonly overlaps with a project’s closeout phase, and teams have learned how to work it in.

Air Testing

The amount of testing required on each project is very specific to the design.

On the plus side, testing can save time and energy compared with doing a flush-out. However, projects have historically shied away from this credit option because of the uncertainty of the result. Even with the best specifications, materials may sneak into projects that don’t meet emissions requirements. This can result in gaining conclusive information on air quality—but at the expense of not earning the credit!

In addition to project-specific factors, the testing requirements for LEED v4 remain relatively new and LEED practitioners are still learning what companies can offer relevant services, and at what costs. We have gathered the following anecdotal data for this report.

We are seeing an average of $750–$950 per test kit.

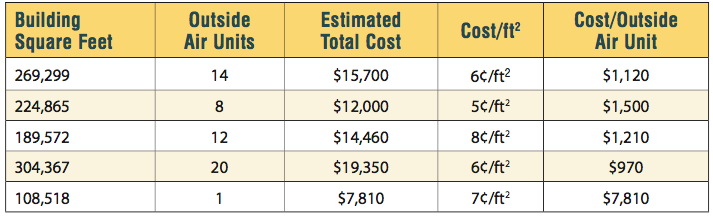

The following are actual costs for LEED projects in the Eastern U.S. pursuing LEED Pilot Credit 68: IAQ procedure, which has an option similar to the LEED v4 credit. Costs per square foot and by number of outside air units are provided for reference.