Effective waste diversion on the jobsite starts with an effective CWM plan.

Photo – Tristan RobertsIn this new prerequisite in LEED v4, project teams are asked to develop and implement a construction waste management (CWM) plan that targets reducing waste that is sent to landfill. There are no performance thresholds for this prerequisite. The construction waste management plan has to identify five targeted materials for diversion; however, the final reported numbers does not have to adhere to stated diversion targets. Teams pursuing the corresponding Construction and Demolition Waste Management credit should be aware of additional requirements for the final waste report. Teams will benefit from studying the requirements of the Construction and Demolition Waste Management credit before developing their plan to verify which option, if any, they will use for that credit.

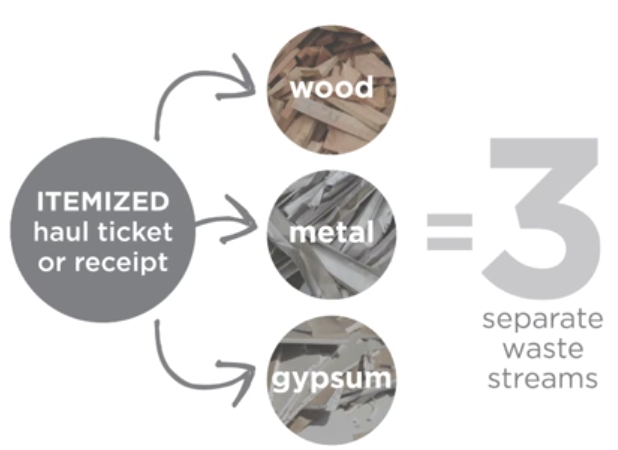

LEED encourages the construction waste management plan to separate the targeted materials streams at the site, a process called source separation, as the most effective method to recycle and reuse materials. Common source separated materials include wood, gypsum board, metals, and masonry. LEED also recognizes that sometimes source separation is not possible and allows the waste plan to account for this. If the project is pursuing the corresponding Construction and Demolition Waste Management credit, the plan needs to align with credit requirements.

Who Is Responsible for Documentation?

The general contractor should provide a waste report detailing all major waste streams generated and include disposal and diversion rates.

Key Terms and Concepts to Know

What are material streams?

The LEED Reference Guide defines streams as flows of materials coming from a job site into markets for building materials. Typically, a single material goes to a single waste stream; however, there are cases where a single type of material could go to multiple waste streams and, conversely, where multiple materials go to a single waste stream.

Typically a single material goes to a single waste stream.

Image – USGBCAn easy way to understand your streams is to focus on the heaviest waste or the waste that generates the most volume. As a best practice, a material stream should constitute at least 5% by weight or volume of total diverted materials. Teams must divert multiple material streams to earn Option 1 of the corresponding credit.

Onsite separation vs. commingled collection

Teams must include collection and sorting methods as part of their CWM plans. Depending on what is appropriate, projects may use a combination of onsite separation and commingled collection. In addition, teams may consider other waste stream diversion tactics like deconstructed materials sent to reuse markets, reuse of deconstructed materials, and takeback programs from manufacturers.

In onsite separation, materials are sorted in dumpsters before they leave the site and are each counted as separate waste streams.

Image – USGBCTo count toward the corresponding credit, commingled recycling facilities must be able to provide project-specific diversion rates or an average diversion rate for the facility that is regulated by the local or state authority. Visual inspection is not an acceptable method of evaluating diversion rates.

If the commingled recycling facility can track and produce documentation of specific materials recycled for your project, you can count commingled waste as multiple waste streams.

Otherwise, commingled waste that is average diversion rate for a regulated facility sent to the same recycling sorting facility is counted as a single waste stream regardless of how many different materials are included. The average recycling rate for the facility must exclude alternative daily cover (ADC).

Source reduction now counted as a viable option

The credit addresses a new way of achieving CWM—via source reduction. Source reduction eliminates project waste through prefabrication, modular construction, or incorporating standard material lengths or sizes into the project’s design to eliminate waste.

To get the most benefit, this option requires teams to plan for source reduction during design and implement it during construction. Teams planning to utilize source reduction as the credit achievement option should address its use in their CWM plan.

Alternative Daily Cover (ADC) does not count

There’s a big change in CWM from previous versions of LEED. Alternative daily cover (ADC) no longer qualifies as diversion. Any materials that are used for ADC must be counted as landfilled and your CWM plan must account for this.

Land-clearing debris and hazardous materials are still out but must be accounted for

Similar to LEED 2009, land-clearing debris materials that are natural (like rock, soil, stone, and vegetation) are not considered construction, demolition, or renovation waste. Consequently, teams should not include these materials in their calculations, although their CWM plans must account for these materials.

Similarly, teams must document the safe removal and disposal of hazardous materials in their CWM plans but exclude these materials in their calculations.

Incineration can be considered diversion in certain cases

In a new development for LEED v4, incineration can be diversion, but only if reuse and recycling methods are not readily available in the project’s location and a team can demonstrate they exhausted these strategies before sending waste material to energy facilities.

In those cases, waste-to-energy incineration may be considered diversion and it must be included in the CWM plan. Teams must follow European Commission Waste Framework and Incineration Directives and the waste-to-energy facility must meet the applicable European standards based on fuel type.

Note: The combustion of waste wood (“wood-derived fuel” or biofuel) is considered diversion and is not subject to the additional requirements for waste-to-energy incineration. The definition of a wood-derived fuel is basically if the waste is made into a product that can be sold for another use like fuel.

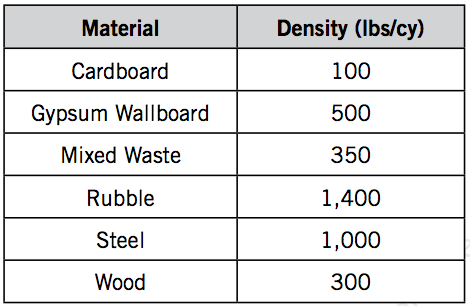

Waste report can be by weight or volume

Teams can calculate the diversion rate by weight or volume as long as they are consistent. The diversion rate is calculated by dividing the total waste diverted from the landfill by the total waste generated by the project and multiplying the result by 100.

Solid waste conversion factors

LEED Reference GuideOther waste diversion strategies

Teams may consider other waste stream diversion tactics like sending deconstructed materials to reuse markets, reuse of deconstructed materials, and takeback programs from manufacturers.

Deconstructed materials can be donated to charity or sent to another project site. Much like commingled waste, donation also counts as a single waste stream unless the receiving organization can verify and track the individual materials that are donated. This is another example of a multiple material types constituting a single waste stream when additional documentation is not available.

For deconstructed materials that are reused onsite, no distinction is made between whether the materials are serving their original function or not. In this case, each material reused onsite for each purpose counts as a single waste stream.

Take back programs for single material types are single waste streams.

Image – USGBC