Waste management can occur through onsite reuse, as with this masonry material.

Option 1: Diversion percentages with a new twist

Similar to LEED 2009, Option 1 focuses on diverting construction and demolition waste from landfills by finding alternatives, including recycling or salvaging (via reuse on site, donation for reuse on another site, or resale).

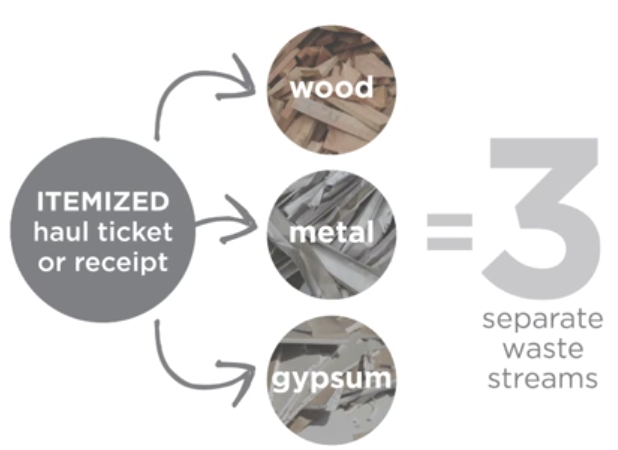

The credit requires teams to divert both a percentage of overall waste and a certain number of material or waste streams, giving two options for compliance. Path 1 requires 50% diversion of the total construction and demolition debris and at least three material streams. Path 2 requires 75% diversion and at least four material streams. Yes, demolition of previously existing buildings, parts of buildings, etc. are included in credit calculations. This means that documentation of the credit starts as soon as demolition does and these waste streams must be measured.

Option 2: Reduction of Total Waste Requires Integrated Design Thinking

LEED v4 offers a new alternative to diversion: source reduction.

Option 1 will be fairly familiar to teams who worked on LEED 2009 projects, and, aside from defining material or waste streams, should be fairly straightforward to document.

As an alternative to diversion, Option 2 will require teams to think about and plan for not generating waste in the first place, which is a new way of dealing with construction waste reduction for LEED. Option 2 directs teams to reduce total waste material and not generate more than 2.5 lbs/ft2 (12.2 kg/m2) of the building’s floor area.

To implement this option requires that building be designed to generate less waste from the very beginning. Design strategies such as prefabrication, modular construction, or using standard material lengths or sizes into the project’s design can all help reduce waste for this path to the credit. To get the most benefit, this option requires teams to plan for source reduction during design and implement it during construction.

Before using Option 2, teams should estimate the amount of waste for the project to determine if the performance threshold is realistic. If viable, teams should address the use of source reduction in their construction waste management (CWM) plan developed for the corresponding prerequisite to this credit.